Page 277 - CITS - Welder - Trade Practical

P. 277

WELDER - CITS

Maintain a short arc to get uniform fusion and root penetration.

Note : Avoid side-to-side movement of the electrode.

Deslag and clean the root bead thoroughly.

Deposit the final covering run and 160 amp current.

Give side-to-side movement to the electrode not more than 2.5 times its dia.

Use the same electrode angle as was used for the root bead.

Note : Prevent the upper edge of the plate from melting off by not allowing the arc to concentrate

more on the upper edge

Remove the slag with a chipping hammer.

Clean the weld with a steel wire brush.

Inspect the Corner/fillet weld and ensure: comer

- It has equal leg length with slight convexity

- The upper edge of the plate has not melted off

- It is free from surface defects.

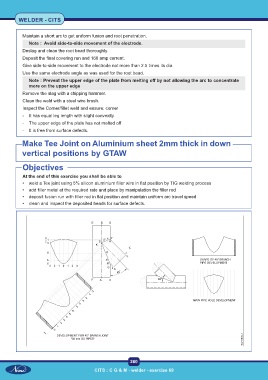

Make Tee Joint on Aluminium sheet 2mm thick in down

vertical positions by GTAW

Objectives

At the end of this exercise you shall be able to

• weld a Tee joint using 5% silicon aluminium filler wire in flat position by TIG welding process

• add filler metal at the required rate and place by manipulation the filler rod

• deposit fusion run with filler rod in flat position and maintain uniform arc travel speed

• clean and inspect the deposited beads for surface defects.

260

CITS : C G & M - welder - exercise 69