Page 316 - CITS - Welder - Trade Practical

P. 316

WELDER - CITS

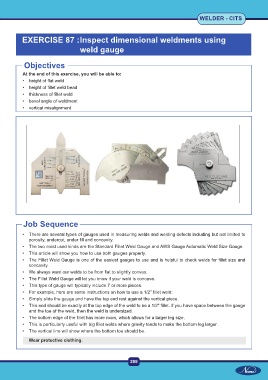

EXERCISE 87 : Inspect dimensional weldments using

weld gauge

Objectives

At the end of this exercise, you will be able to:

• height of flat weld

• height of fillet weld bead

• thickness of fillet weld

• bevel angle of weldment

• vertical misalignment.

Job Sequence

• There are several types of gauges used in measuring welds and welding defects including but not limited to

porosity, undercut, under fill and concavity.

• The two most used kinds are the Standard Fillet Weld Gauge and AWS Gauge Automatic Weld Size Gauge.

• This article will show you how to use both gauges properly.

• The Fillet Weld Gauge is one of the easiest gauges to use and is helpful to check welds for fillet size and

concavity.

• We always want our welds to be from flat to slightly convex.

• The Fillet Weld Gauge will let you know if your weld is concave.

• This type of gauge will typically include 7 or more pieces.

• For example, here are some instructions on how to use a 1/2″ fillet weld:

• Simply slide the gauge and have the top end rest against the vertical piece.

• This end should be exactly at the top edge of the weld to be a 1/2″ fillet. If you have space between the gauge

and the toe of the weld, then the weld is undersized.

• The bottom edge of the fillet has more room, which allows for a larger leg size.

• This is particularly useful with big fillet welds where gravity tends to make the bottom leg larger.

• The vertical line will show where the bottom toe should be.

Wear protective clothing.

299