Page 320 - CITS - Welder - Trade Practical

P. 320

WELDER - CITS

EXERCISE 90: Evaluate welding defects using Dye

penetrant

Objectives

At the end of this exercise, you will be able to:

• Kit spray penetrating stains (penetrant, cleaner, developer) to solvent removal technique visible agent

(Type II, Method C)

• Luxmeter

• Gloves and masks

• Industrial rag.

Job Sequence

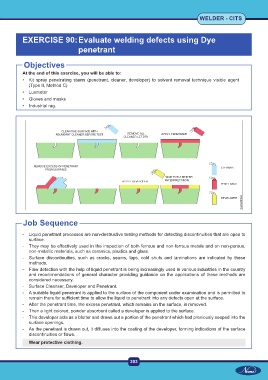

- Liquid penetrant processes are non-destructive testing methods for detecting discontinuities that are open to

surface.

- They may be effectively used in the inspection of both ferrous and non-ferrous metals and on non-porous,

non-metallic materials, such as ceramics, plastics and glass.

- Surface discontinuities, such as cracks, seams, laps, cold shuts and laminations are indicated by these

methods.

- Flaw detection with the help of liquid penetrant is being increasingly used in various industries in the country

and recommendations of general character providing guidance on the applications of these methods are

considered necessary.

- Surface Cleanser, Developer and Penetrant.

- A suitable liquid penetrant is applied to the surface of the component under examination and is permitted to

remain there for sufficient time to allow the liquid to penetrant into any defects open at the surface.

- After the penetrant time, the excess penetrant, which remains on the surface, is removed.

- Then a light colored, powder absorbent called a developer is applied to the surface.

- This developer acts as a blotter and draws out a portion of the penetrant which had previously seeped into the

surface openings.

- As the penetrant is drawn out, it diffuses into the coating of the developer, forming indications of the surface

discontinuities or flaws.

Wear protective clothing.

303