Page 91 - CITS - Welder - Trade Practical

P. 91

WELDER - CITS

• Check the alignment of pieces, clean the tacks, and place on the welding table in a flat position.

• Start welding, using leftward technique with the correct angle of the blowpipe and (3mm ø) filler rod.

• Fuse the edges uniformly, add filler metal to obtain correct root fusion and reinforcement, and proceed towards

left. Don’t concentrate the flame on the top member in the lap joint.

• Maintain correct travel speed, manipulation of blowpipe and filler rod to produce uniform weld bead.

• Stop at the left end, after filling the crater and complete the weld.

• Extinguish the flame, cool the nozzle in water and place the blowpipe at its place on the cylinder trolley.

• Clean the welded joint with a wire brush.

Visual inspection: Inspect for correct size of fillet weld, slight convexity, uniform width and height, uniform ripples

without edge of plate melted off defect and other surface defects.Weld the job from the other side also following

the same steps.

Repeat the exercise till you get good results.

Skill Sequence

Lap weld joint on MS sheet 2.00 mm in flat position

Objectives: At the end of this exercise you shall be able to

• prepare and lap weld joint on MS plate 2.00mm in flat position.

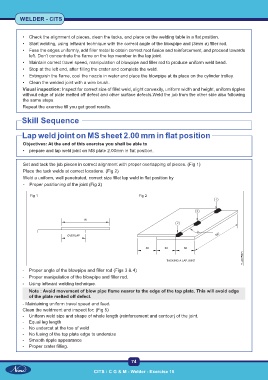

Set and tack the job pieces in correct alignment with proper overlapping of pieces. (Fig 1)

Place the tack welds at correct locations. (Fig 2)

Weld a uniform, well penetrated, correct size fillet lap weld in flat position by

- Proper positioning of the joint (Fig 2)

Fig 1 Fig 2

- Proper angle of the blowpipe and filler rod (Figs 3 & 4)

- Proper manipulation of the blowpipe and filler rod.

- Using leftward welding technique.

Note : Avoid movement of blow pipe flame nearer to the edge of the top plate. This will avoid edge

of the plate melted off defect.

- Maintaining uniform travel speed and feed.

Clean the weldment and inspect for: (Fig 5)

- Uniform weld size and shape of whole length (reinforcement and contour) of the joint.

- Equal leg length

- No undercut at the toe of weld

- No fusing of the top plate edge to undersize

- Smooth ripple appearance

- Proper crater filling.

74

CITS : C G & M - Welder - Exercise 15