Page 87 - CITS - Welder - Trade Practical

P. 87

WELDER - CITS

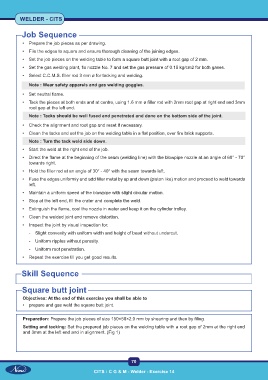

Job Sequence

• Prepare the job pieces as per drawing.

• File the edges to square and ensure thorough cleaning of the joining edges.

• Set the job pieces on the welding table to form a square butt joint with a root gap of 2 mm.

• Set the gas welding plant, fix nozzle No. 7 and set the gas pressure of 0.15 kg/cm2 for both gases.

• Select C.C.M.S. filler rod 3 mm ø for tacking and welding.

Note : Wear safety apparels and gas welding goggles.

• Set neutral flame.

• Tack the pieces at both ends and at centre, using 1.6 mm ø filler rod with 2mm root gap at right end and 3mm

root gap at the left end.

Note : Tacks should be well fused and penetrated and done on the bottom side of the joint.

• Check the alignment and root gap and reset if necessary.

• Clean the tacks and set the job on the welding table in a flat position, over fire brick supports.

Note : Turn the tack weld side down.

• Start the weld at the right end of the job.

• Direct the flame at the beginning of the seam (welding line) with the blowpipe nozzle at an angle of 60° - 70°

towards right.

• Hold the filler rod at an angle of 30° - 40° with the seam towards left.

• Fuse the edges uniformly and add filler metal by up and down (piston like) motion and proceed to weld towards

left.

• Maintain a uniform speed of the blowpipe with slight circular motion.

• Stop at the left end, fill the crater and complete the weld.

• Extinguish the flame, cool the nozzle in water and keep it on the cylinder trolley.

• Clean the welded joint and remove distortion.

• Inspect the joint by visual inspection for:

- Slight convexity with uniform width and height of bead without undercut.

- Uniform ripples without porosity.

- Uniform root penetration.

• Repeat the exercise till you get good results.

Skill Sequence

Square butt joint

Objectives: At the end of this exercise you shall be able to

• prepare and gas weld the square butt joint.

Preparation: Prepare the job pieces of size 150×50×2.0 mm by shearing and then by filing.

Setting and tacking: Set the prepared job pieces on the welding table with a root gap of 2mm at the right end

and 3mm at the left end and in alignment. (Fig 1)

70

CITS : C G & M - Welder - Exercise 14