Page 101 - CITS - Welder - Trade Theory

P. 101

WELDER - CITS

Aluminium Properties and weldability

Objectives : At the end of this lesson you shall be able to

• explain the properties of aluminium and its alloys

• state the difficulties in welding of aluminium by oxy-acetylene process

• describe the joint design, importance of flux and welding procedure

• state the various process of welding aluminium

• explain the advantages and disadvantages of welding of aluminium by oxy-acetylene process.

Add the filler rod by holding it close to the cone of the flame. Upon withdrawing it from the puddle remove it

entirely from the flame until you are ready to dip it back into the puddle.

Properties of aluminum its alloys

i Silvery white in colour.

i Weighs only about one third as much as the commonly used low carbon steel.

iii Highly resistant to corrosion.

iv Possesses great electrical and thermal conductivity.

v Very ductile, adaptable for forming and pressing adaptable for forming and pressing operations.

vi Non-magnetic.

vii Melting point of pure aluminum is 659°C.

viii Aluminum oxide has a higher melting point (1930°C) than aluminum.

Types

Aluminum is classified into three main groups.

1 Commercially pure aluminum

2 Wrought alloys

3 Aluminum cast alloys

Commercially pure aluminum has a purity of at least 99% the remaining 1% consisting of iron and silicon.

Difficulties in welding of aluminum by gas:

Aluminum does not change in colour before it reaches the melting temperature. When the metal begins to melt,

it collapses suddenly.

Molten aluminum oxidizes very rapidly form a heavy coating of aluminum oxide on the surface of the seam

which has a higher melting point – 1930°C. This oxide must be thoroughly removed by using a good quality flux.

Aluminum, when hot, is very flimsy and weak. Care must be taken to support it adequately during the welding

operation.

Joint design:

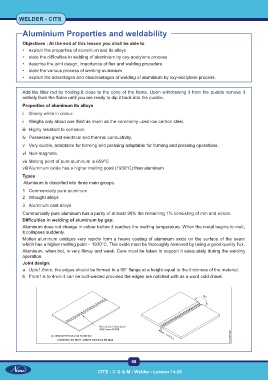

a Upto1.6mm, the edges should be formed to a 90° flange at a height equal to the thickness of the material.

b From1.6 to 4mm it can be butt-welded provided the edges are notched with as a word cold chisel.

88

CITS : C G & M - Welder - Lesson 14-26 CITS : C G & M - Welder - Lesson 14-26