Page 98 - CITS - Welder - Trade Theory

P. 98

WELDER - CITS

7 Cracks

A discontinuity in the base metal or weld metal or both.

Causes - Not have similar both base metal. Base metal and filler rod not similar .Not proper pre-heat Weld metal

cooling very fast. not proper heat treatment.

Remedies - Similar need both base metal. Base metal and filler rod similar need. proper pre-heat need. Weld

metal cooling slow need. proper heat treatment need.

Classification of steels Welding of low carbon steel, medium

and high carbon steel and alloy steels

Objectives : At the end of this lesson you shall be able to

• state the main classification of steels

• explain the effect of carbon content in steel

• describe the uses of various types of carbon steel.

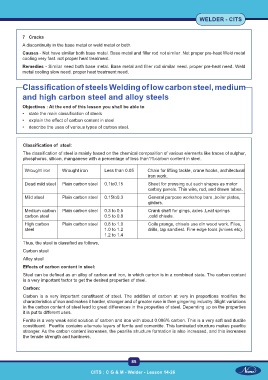

Classification of steel:

The classification of steel is mainly based on the chemical composition of various elements like traces of sulphur,

phosphorus, silicon, manganese with a percentage of less than1%carbon content in steel.

Wrought iron Wrought iron Less than 0.05 Chain for lifting tackle, crane hooks, architectural

iron work.

Dead mild steel Plain carbon steel 0.1to0.15 Sheet for pressing out such shapes as motor

carboy panels. Thin wire, rod, and drawn tubes.

Mild steel Plain carbon steel 0.15to0.3 General purpose workshop bars ,boiler plates,

girders.

Medium carbon Plain carbon steel 0.3 to 0.5 Crank shaft for gings, axles .Leaf springs

carbon steel 0.5 to 0.8 ,cold chisels.

High carbon Plain carbon steel 0.8 to 1.0 Coils prangs, chisels use din wood work. Files,

steel 1.0 to 1.2 drills, tap sandiest. Fine edge tools (knives etc).

1.2 to 1.4

Thus, the steel is classified as follows,

Carbon steel

Alloy steel

Effects of carbon content in steel:

Steel can be defined as an alloy of carbon and iron, in which carbon is in a combined state. The carbon content

is a very important factor to get the desired properties of steel.

Carbon:

Carbon is a very important constituent of steel. The addition of carbon at very in proportions modifies the

characteristics of iron and makes it harder, stronger and of greater ruse in then gingering industry. Slight variations

in the carbon content of steel lead to great differences in the properties of steel. Depending up on the properties

it is put to different uses.

Ferrite is a very weak solid solution of carbon and iron with about 0.006% carbon. This is a very soft and ductile

constituent. Pearlite contains alternate layers of ferrite and cementite. This laminated structure makes pearlite

stronger. As the carbon content increases, the pearlite structure formation is also increased, and this increases

the tensile strength and hardness.

85

CITS : C G & M - Welder - Lesson 14-26 CITS : C G & M - Welder - Lesson 14-26