Page 94 - CITS - Welder - Trade Theory

P. 94

WELDER - CITS

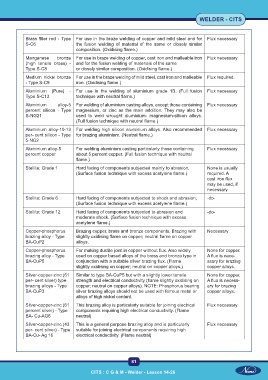

Brass filler rod - Type For use in the braze welding of copper and mild steel and for Flux necessary

S-C6 the fusion welding of material of the same or closely similar

composition. (Oxidising flame.)

Manganese bronze For use in braze welding of copper, cast iron and malleable iron Flux necessary

(high tensile brass) - and for the fusion welding of materials of the same

Type S-C8 or closely similar composition. (Oxidising flame.)

Medium nickel bronze For use in the braze welding of mild steel, cast iron and malleable Flux required.

- Type S-C9 iron. (Oxidising flame.)

Aluminium (Pure) - For use in the welding of aluminium grade 1B. (Full fusion Flux necessary

Type S-C13 technique with neutral flame.)

Aluminium alloy-5 For welding of aluminium casting alloys, except those containing Flux necessary

percent silicon - Type magnesium, or zinc as the main addition. They may also be

S-NG21 used to weld wrought aluminium- magnesium-silicon alloys.

(Full fusion technique with neutral flame.)

Aluminium alloy-10-13 For welding high silicon aluminium alloys. Also recommended Flux necessary

per- cent silicon - Type for brazing aluminium. (Neutral flame.)

5-NG2

Aluminium alloy-5 For welding aluminium casting particularly those containing Flux necessary

percent copper about 5 percent copper. (Full fusion technique with neutral

flame.)

Stellite: Grade 1 Hard facing of components subjected mainly to abrasion. None is usually

(Surface fusion technique with excess acetylene flame.) required. A

cast iron flux

may be used, if

necessary

Stellite: Grade 6 Hard facing of components subjected to shock and abrasion, -do-

(Surface fusion technique with excess acetylene flame.)

Stellite: Grade 12 Hard facing of components subjected to abrasion and -do-

moderate shock. (Surface fusion technique with excess

acetylene flame.)

Copper-phosphorus Brazing copper, brass and bronze components. Brazing with Necessary

brazing alloy - Type slightly oxidising flame on copper; neutral flame on copper

BA-CuP2 alloys.

Copper-phosphorus For making ductile joint in copper without flux. Also widely None for copper.

brazing alloy - Type used on copper based alloys of the brass and bronze type in A flux is nece-

BA-CuP5 conjunction with a suitable silver brazing flux. (Flame ssary for brazing

slightly oxidising on copper; neutral on copper alloys.) copper alloys.

Silver-copper-zinc (61 Similar to type BA-CuP5 but with a slightly lower tensile None for copper.

per- cent silver) type strength and electrical conductivity (flame slightly oxidising on A flux is necess-

brazing alloys - Type copper; neutral on copper alloys). NOTE: Phosphorus bearing ary for brazing

BA-CuP3 silver brazing alloys should not be used with ferrous metal or copper alloys.

alloys of high nickel content.

Silver-copper-zinc (61 This brazing alloy is particularly suitable for joining electrical Flux necessary

percent silver) - Type components requiring high electrical conductivity. (Flame

BA- Cu-AG6 neutral)

Silver-copper-zinc (43 This is a general purpose brazing alloy and is particularly Flux necessary

per- cent silver) - Type suitable for joining electrical components requiring high

BA-Cu- Ag 16 electrical conductivity. (Flame neutral)

81

CITS : C G & M - Welder - Lesson 14-26 CITS : C G & M - Welder - Lesson 14-26