Page 89 - CITS - Welder - Trade Theory

P. 89

WELDER - CITS

8.0 25

10.0 35

12.0 45

19.0 55

25.0 70

Over 25 .0 90

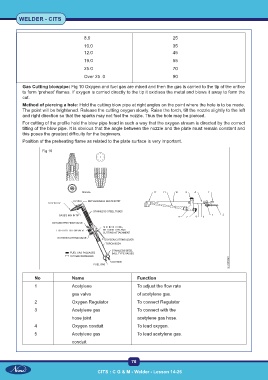

Gas Cutting blowpipe: Fig 10 Oxygen and fuel gas are mixed and then the gas is carried to the tip of the orifice

to form ‘preheat’ flames. If oxygen is carried directly to the tip it oxidises the metal and blows it away to form the

cut.

Method of piercing a hole: Hold the cutting blow pipe at right angles on the point where the hole is to be made.

The point will be brightened. Release the cutting oxygen slowly. Raise the torch, tilt the nozzle slightly to the left

and right direction so that the sparks may not fuel the nozzle. Thus the hole may be pierced.

For cutting of the profile hold the blow pipe head in such a way that the oxygen stream is directed by the correct

tilting of the blow pipe. It is obvious that the angle between the nozzle and the plate must remain constant and

this poses the greatest difficulty for the beginners.

Position of the preheating flame as related to the plate surface is very important.

Fig 10

No Name Function

1 Acetylene To adjust the flow rate

gas valve of acetylene gas.

2 Oxygen Regulator To connect Regulator

3 Acetylene gas To connect with the

hose joint acetylene gas hose.

4 Oxygen conduit To lead oxygen.

5 Acetylene gas To lead acetylene gas.

conduit

76

CITS : C G & M - Welder - Lesson 14-26 CITS : C G & M - Welder - Lesson 14-26