Page 87 - CITS - Welder - Trade Theory

P. 87

WELDER - CITS

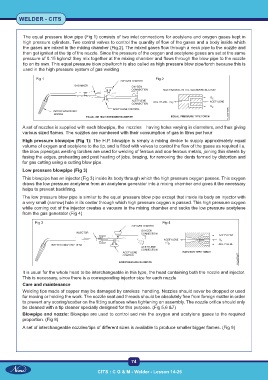

The equal pressure blow pipe (Fig.1) consists of two inlet connections for acetylene and oxygen gases kept in

high pressure cylinders. Two control valves to control the quantity of flow of the gases and a body inside which

the gases are mixed in the mixing chamber (Fig.2). The mixed gases flow through a neck pipe to the nozzle and

then get ignited at the tip of the nozzle. Since the pressure of the oxygen and acetylene gases are set at the same

pressure of 0.15 kg/cm2 they mix together at the mixing chamber and flows through the blow pipe to the nozzle

tip on its own. This equal pressure blow pipe/torch is also called as high pressure blow pipe/torch because this is

used in the high pressure system of gas welding

Fig 1 Fig 2

A set of nozzles is supplied with each blowpipe, the nozzles having holes varying in diameters, and thus giving

various sized flames. The nozzles are numbered with their consumption of gas in litres per hour

High pressure blowpipe (Fig 1): The H.P. blowpipe is simply a mixing device to supply approximately equal

volume of oxygen and acetylene to the tip, and is fitted with valves to control the flow of the gases as required i.e,

the blow pipes/gas welding torches are used for welding of ferrous and non-ferrous metals, joining thin sheets by

fusing the edges, preheating and post heating of jobs, brazing, for removing the dents formed by distortion and

for gas cutting using a cutting blow pipe.

Low pressure blowpipe (Fig 3)

This blowpipe has an injector (Fig 3) inside its body through which the high pressure oxygen passes. This oxygen

draws the low pressure acetylene from an acetylene generator into a mixing chamber and gives it the necessary

helps to prevent backfiring.

The low pressure blow pipe is similar to the equal pressure blow pipe except that inside its body an injector with

a very small (narrow) hole in its center through which high pressure oxygen is passed. This high pressure oxygen

while coming out of the injector creates a vacuum in the mixing chamber and sucks the low pressure acetylene

from the gas generator (Fig 4)

Fig 3 Fig 4

It is usual for the whole head to be interchangeable in this type, the head containing both the nozzle and injector.

This is necessary, since there is a corresponding injector size for each nozzle

Care and maintenance

Welding tips made of copper may be damaged by careless handling. Nozzles should never be dropped or used

for moving or holding the work. The nozzle seat and threads should be absolutely free from foreign matter in order

to prevent any scoring/scatter on the fitting surfaces when tightening on assembly. The nozzle orifice should only

be cleaned with a tip cleaner specially designed for this purpose. (Fig 5,6 &7)

Blowpipe and nozzle: Blowpipe are used to control and mix the oxygen and acetylene gases to the required

proportion. (Fig 8)

A set of interchangeable nozzles/tips of different sizes is available to produce smaller bigger flames. (Fig 9)

74

CITS : C G & M - Welder - Lesson 14-26 CITS : C G & M - Welder - Lesson 14-26