Page 86 - CITS - Welder - Trade Theory

P. 86

WELDER - CITS

When the spindle of the cylinder is opened slowly, the high pressure gas from the cylinder enters into the regulator

through the gas then enters the body of the regulator which is controlled by the needle valve. The pressure

inside the regulator rises which pushes the diaphragm and the valve to which it is attached, closes the valve and

prevents any more gas from entering the regulator. The outlet side is fitted with a pressure gauge which indicates

the working pressure on the blowpipe. Upon the gas being drawn ‘off from the outlet side, the pressure inside the

regulator body falls, the diaphragm is pushed back by the spring and the valve opens, letting more gas ‘in’ from

the cylinder. The pressure in the body, therefore, depends on the pressure of the springs and this can be adjusted

by means of a regulator knob.

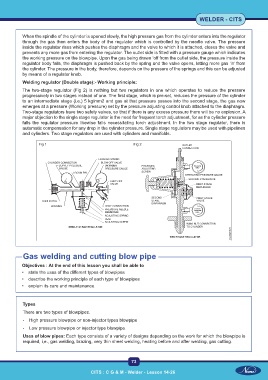

Welding regulator (Double stage):- Working principle:

The two-stage regulator (Fig 2) is nothing but two regulators in one which operates to reduce the pressure

progressively in two stages instead of one. The first stage, which is pre-set, reduces the pressure of the cylinder

to an intermediate stage (i.e.) 5 kg/mm2 and gas at that pressure passes into the second stage, the gas now

emerges at a pressure (Working pressure) set by the pressure adjusting control knob attached to the diaphragm.

Two-stage regulators have two safety valves, so that if there is any excess pressure there will be no explosion. A

major objection to the single stage regulator is the need for frequent torch adjustment, for as the cylinder pressure

falls the regulator pressure likewise falls necessitating torch adjustment. In the two stage regulator, there is

automatic compensation for any drop in the cylinder pressure. Single stage regulators may be used with pipelines

and cylinders. Two stage regulators are used with cylinders and manifolds.

Fig 1 Fig 2

Gas welding and cutting blow pipe

Objectives : At the end of this lesson you shall be able to

• state the uses of the different types of blowpipes

• describe the working principle of each type of blowpipes

• explain its care and maintenance.

Types

There are two types of blowpipes.

- High pressure blowpipe or non-injector types blowpipe

- Low pressure blowpipe or injector type blowpipe.

Uses of blow pipes: Each type consists of a variety of designs depending on the work for which the blowpipe is

required, i,e., gas welding, brazing, very thin sheet welding, heating before and after welding, gas cutting.

73

CITS : C G & M - Welder - Lesson 14-26 CITS : C G & M - Welder - Lesson 14-26