Page 90 - CITS - Welder - Trade Theory

P. 90

WELDER - CITS

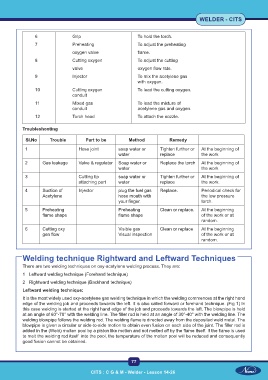

6 Grip To hold the torch.

7 Preheating To adjust the preheating

oxygen valve flame.

8 Cutting oxygen To adjust the cutting

valve oxygen flow rate.

9 Injector To mix the acetylene gas

with oxygen.

10 Cutting oxygen To lead the cutting oxygen.

conduit

11 Mixed gas To lead the mixture of

conduit acetylene gas and oxygen.

12 Torch head To attach the nozzle.

Troubleshooting

SI.No Trouble Part to be Method Remedy

1 Hose joint soap water or Tighten further or At the beginning of

water replace the work

2 Gas leakage Valve & regulator Soap water or Replace the torch At the beginning of

water the work

3 Cutting tip soap water or Tighten further or At the beginning of

attaching part water replace the work.

4 Suction of Injector plug the fuel gas Replace. Periodical check for

Acetylene hose mouth with the low pressure

your finger. torch.

5 Preheating Preheating Clean or replace. At the beginning

flame shape flame shape of the work or at

random.

6 Cutting oxy Visible gas Clean or replace At the beginning

gen flow Visual inspection of the work or at

random.

Welding technique Rightward and Leftward Techniques

There are two welding techniques on oxy-acetylene welding process. They are:

1 Leftward welding technique (Forehand technique)

2 Rightward welding technique (Backhand technique)

Leftward welding technique:

It is the most widely used oxy-acetylene gas welding technique in which the welding commences at the right hand

edge of the welding job and proceeds towards the left. It is also called forward or forehand technique. (Fig 1) In

this case welding is started at the right hand edge of the job and proceeds towards the left. The blowpipe is held

at an angle of 60°-70° with the welding line. The filler rod is held at an angle of 30°-40° with the welding line. The

welding blowpipe follows the welding rod. The welding flame is directed away from the deposited weld metal. The

blowpipe is given a circular or side-to-side motion to obtain even fusion on each side of the joint. The filler rod is

added in the (Weld) molten pool by a piston like motion and not melted off by the flame itself. If the flame is used

to melt the welding rod itself into the pool, the temperature of the molten pool will be reduced and consequently

good fusion cannot be obtained.

77

CITS : C G & M - Welder - Lesson 14-26 CITS : C G & M - Welder - Lesson 14-26