Page 93 - CITS - Welder - Trade Theory

P. 93

WELDER - CITS

In certain rare cases, it may be necessary to use filler rods of composition not covered by these specifications; in

such cases filler rods with well established performances should be used. To select a filler rod in respect to the

metal to be welded, the filler rod must have the same composition with respect to the base metal to be welded.

Factors to be considered for selection of filler rod are:

a The type and composition of base metal

b The base metal thickness

c The type of edge preparation

d The weld is deposited as root run, intermediate runs or final covering run

e Welding position

f Whether there is any corrosion effect or loss of material from the base metal due to welding.

Care and maintenance

1 Filler rods should be stored in clean, dry condition to prevent deterioration.

2 Do not mix different types of filler rods.

3 Ensure that packages and their labels are in order for easy and correct selection.

4 Where it is not practicable to store filler rods under heated conditions, an absorbent for moisture such as silica-

gel may be used in the storage area.

5 Ensure the rod is free from contamination such as rust, scale, oil, grease and moisture.

6 Ensure the rod is reasonably straight to assist manipulation during welding.

Each metal requires a suitable filler rod. Refer to IS : 1278 - 1972 and IS : 2927 - 1975 attached.

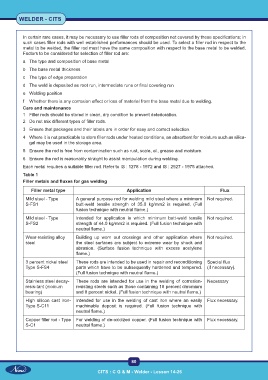

Table 1

Filler metals and fluxes for gas welding

Filler metal type Application Flux

Mild steel - Type A general purpose rod for welding mild steel where a minimum Not required.

S-FS1 butt-weld tensile strength of 35.0 kg/mm2 is required. (Full

fusion technique with neutral flame.)

Mild steel - Type Intended for application in which minimum butt-weld tensile Not required.

S-FS2 strength of 44.0 kg/mm2 is required. (Full fusion technique with

neutral flame.)

Wear-resisting alloy Building up worn out crossings and other application where Not required.

steel the steel surfaces are subject to extreme wear by shock and

abrasion. (Surface fusion technique with excess acetylene

flame.)

3 percent nickel steel These rods are intended to be used in repair and reconditioning Special flux

Type S-FS4 parts which have to be subsequently hardened and tempered. (if necessary).

(Full fusion technique with neutral flame.)

Stainless steel decay- These rods are intended for use in the welding of corrosion- Necessary

resis-tant (niobium resisting steels such as those containing 18 percent chromium

bearing) and 8 percent nickel. (Full fusion technique with neutral flame.)

High silicon cast iron- Intended for use in the welding of cast iron where an easily Flux necessary.

Type S-C11 machinable deposit is required. (Full fusion technique with

neutral flame.)

Copper filler rod - Type For welding of de-oxidized copper. (Full fusion technique with Flux necessary.

S-C1 neutral flame.)

80

CITS : C G & M - Welder - Lesson 14-26 CITS : C G & M - Welder - Lesson 14-26