Page 85 - CITS - Welder - Trade Theory

P. 85

WELDER - CITS

9 When storing outside, make sure the cylinders are stored in the designated storage area. Place the cylinders on

a raised concrete pad (or other non-combustible platform) or non combustible rack inside a secure designated

area that is fenced in.

10 The plat form should be designed to prevent the cylinders from corroding from contact with ground, ice, snow,

water, salt, and high temperatures.

11 Unless otherwise instructed, when storing indoors, store the cylinders only in rooms that are specifically

designated. These rooms must meet specific design, electrical, and ventilation requirements as outlined in the

fire, electrical and building codes.

12 Protect cylinders from falling. Secure the cylinders according to the instructions in the safe operating procedure.

Tip! Securing each cylinder separately prevents other cylinders from falling when one of them is removed from

storage.

13 Store acetylene and liquefied gas cylinders valve end up. Close the valve and keep the protective device in

place.

14 Cylinders must also be separated away from flammable products and from materials that easily ignite (such

as wood, paper, oil, grease, etc.).

15 Unless otherwise specified in the safe operating procedure, the general recommendation is to store oxygen

cylinders and fuel gas cylinders separately when “not in use.” This method applies to indoor and outdoor

storage.

16 Separate oxygen from fuel gas cylinders by at least 6.1 m (20 ft), or by a wall at least 1.5m (5 ft) high with a

minimum half-hour fire resistance.

Gas Pressure Regulator

Objectives : At the end of this lesson you shall be able to

• state the different types of regulators

• describe the working principle of a single and double stage regulator

• explain the parts of each type of regulator

• explain the care and maintenance of the regulators.

Introduction

Types of regulators

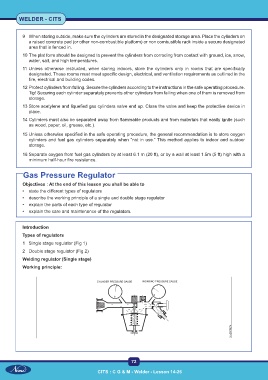

1 Single stage regulator (Fig 1)

2 Double stage regulator (Fig 2)

Welding regulator (Single stage)

Working principle:

72

CITS : C G & M - Welder - Lesson 14-26 CITS : C G & M - Welder - Lesson 14-26