Page 150 - CITS - Welder - Trade Theory

P. 150

WELDER - CITS

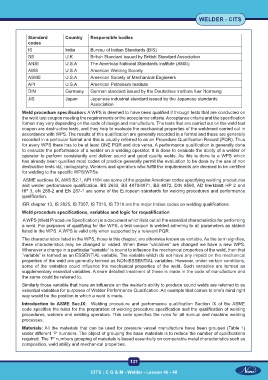

Standard Country Responsible bodies

codes

IS India Bureau of Indian Standards (BIS)

BS U.K British Standard issued by British Standard Association

ANSI U.S.A The American National Standards Institute (ANSI)

AWS U.S.A American Welding Society

ASME U.S.A American Society of Mechanical Engineers

API U.S.A American Petroleum Institute

DIN Germany German standard issued by the Deutsches Institute fuer Normung

JIS Japan Japanese industrial standard issued by the Japanese standards

Association

Weld procedure specification: A WPS is deemed to have been qualified if through tests that are conducted on

the weld test coupon meeting the requirements or the acceptance criteria. Acceptance criteria and the specification

format may vary depending on the code of design and manufacture. The tests that are carried out on the weld test

coupon are destructive tests, and they help to evaluate the mechanical properties of the weldment carried out in

accordance with WPS. The results of this qualification are generally recorded in a format and these are generally

recorded in a particular format and this is usually referred to as an Procedure Qualification Record (PQR). Thus

for every WPS there has to be at least ONE PQR and vice versa. A performance qualification is generally done

to evaluate the performance of a welder on a welding operator. It is done to evaluate the ability of a welder or

operator to perform consistently and deliver sound and good quality welds. As this is done to a WPS which

has already been qualified most codes of practice generally permit the evaluation to be done by the use of non

destructive tests viz, radiography. Welders and operators who fulfill the requirements are deemed to be certified

for welding to the specific WPS/WPSs.

ASME sections IX, AWS B2.1, API 1104 are some of the popular American codes specifying welding procedures

and welder performance qualification. BS 2633, BS 4870/4871, BS 4872, DIN 8560, AD Merkblatt HP 2 and

HP 3, eN 288-2 and EN 287-1 are some of the European standards for welding procedures and performance

qualification.

IBR chapter 13, IS 2825, IS 7307, IS 7310, IS 7318 are the major Indian codes on welding qualifications.

Weld procedure specifications, variables and logic for requalification

A WPS (Weld Procedure Specification) is a document which lists out all the essential characteristics for performing

a weld. For purposes of qualifying for the WPS, a test coupon is welded adhering to all parameters as stated/

listed in the WPS. A WPS is valid only when supported by a relevant PQR.

The characteristics listed in the WPS, those in this chapter, are otherwise known as variable. As the term signifies,

these characteristics may be changed or varied. When these “variables” are changed we have a new WPS.

Whenever a change in a particular “variable” is bound to influence the mechanical properties of the weld, then that

“variable” is termed as an ESSENTIAL variable. The variable which do not have any impact on the mechanical

properties of the weld are generally termed as NON-ESSENTIAL variables. However, under certain conditions,

some of the variables could influence the mechanical properties of the weld. Such variables are termed as

supplementary essential variables. A more detailed treatment of these is made in the code of manufacture and

the same could be referred to.

Similarly those variable that have an influence on the welder’s ability to produce sound welds are referred to as

essential variables for purposes of Welder Performance Qualification. An example that comes to one’s mind right

way would be the position in which a weld is made.

Introduction to ASME Sec.IX: Welding procedure and performance qualification Section IX of the ASME

code specifies the rules for the preparation of welding procedure specification and the qualification of welding

procedures, welders and welding operators. This code specifies the rules for all manual and machine welding

processes.

Materials: All the materials that can be used for pressure vessel manufacture have been grouped (Table 1)

under different ‘P’ numbers. The object of grouping the base materials is to reduce the number of qualifications

required. The ‘P’ numbers grouping of materials is based essentially on comparable metal characteristics such as

composition, weld ability and mechanical properties.

137

CITS : C G & M - Welder - Lesson 46 - 48