Page 62 - CITS - Welder - Trade Theory

P. 62

WELDER - CITS

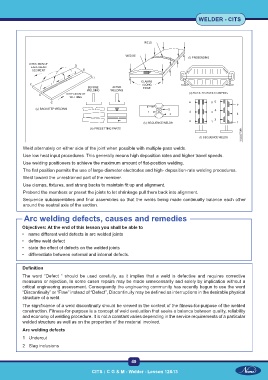

Weld alternately on either side of the joint when possible with multiple-pass welds.

Use low heat input procedures. This generally means high deposition rates and higher travel speeds.

Use welding positioners to achieve the maximum amount of flat-position welding.

The flat position permits the use of large-diameter electrodes and high- deposition-rate welding procedures.

Weld toward the unrestrained part of the member.

Use clamps, fixtures, and strong backs to maintain fit up and alignment.

Prebend the members or preset the joints to let shrinkage pull them back into alignment.

Sequence subassemblies and final assemblies so that the welds being made continually balance each other

around the neutral axis of the section.

Arc welding defects, causes and remedies

Objectives: At the end of this lesson you shall be able to

• name different weld defects in arc welded joints

• define weld defect

• state the effect of defects on the welded joints

• differentiate between external and internal defects.

Definition

The word “Defect “ should be used carefully, as it implies that a weld is defective and requires corrective

measures or rejection, In some cases repairs may be made unnecessarily and solely by implication without a

critical engineering assessment. Consequently the engineering community has recently begun to use the word

“Discontinuity” or “Flaw” instead of “Defect”, Discontinuity may be defined as interruptions in the desirable physical

structure of a weld.

The significance of a weld discontinuity should be viewed in the context of the fitness-for-purpose of the welded

construction. Fitness-for-purpose is a concept of weld evaluation that seeks a balance between quality, reliability

and economy of welding procedure. It is not a constant varies depending in the service requirements of a particular

welded structure as well as on the properties of the material involved.

Arc welding defects

1 Undercut

2 Slag inclusions

49

CITS : C G & M - Welder - Lesson 12&13 CITS : C G & M - Welder - Lesson 12&13