Page 65 - CITS - Welder - Trade Theory

P. 65

WELDER - CITS

Craters : Depression at the termination of a weld head or in the molten weld pool.

Melt-through : A condition resulting when the arc melts through the bottom of a joint welded from one side

Spatter : Metal particles expelled during welding which do not form a part of the weld.

Arc strikes (arc burns): Discontinuities consisting of any localized re melted metal, or change in the surface

profile of any part of a weld or base metal resulting from an arc.

Cracking

This can occur due just to thermal shrinkage or due to a combination of strain accompanying phase change and

thermal shrinkage.

In the case of welded stiff frames, a combination of poor design and inappropriate procedure may result in high

residual stresses and cracking. Where alloy steels or steels with a carbon content greater than about 0.2%

are being welded, self cooling may be rapid enough to cause some (brittle) marten site to form. This will easily

develop cracks.

To prevent these problems a process of pre-heating in stages may be needed and after welding a slow controlled

post cooling in stages will be required. This can greatly increase the cost of welded joins, but for high strength

steels, such as those used in petrochemical plant and piping, there may well be no alternative.

Types of Cracking

Solidification Cracking

This is also called centre line or hot cracking. They are called hot cracks because they occur immediately after

welds are completed and sometimes while the welds are being made. These defects, which are often caused by

sulphur and phosphorus, are more likely to occur in higher carbon steels.

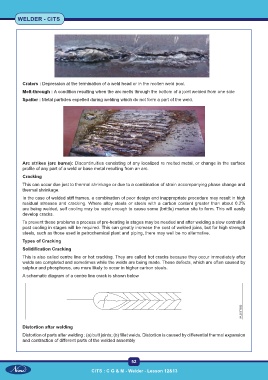

A schematic diagram of a centre line crack is shown below

Distortion after welding

Distortion of parts after welding : (a) butt joints; (b) fillet welds. Distortion is caused by differential thermal expansion

and contraction of different parts of the welded assembly

52

CITS : C G & M - Welder - Lesson 12&13