Page 60 - CITS - Welder - Trade Theory

P. 60

WELDER - CITS

Weld stresses, distortion and methods of control

Objectives: At the end of this lesson you shall be able to

• explain the causes of distortion

• describe the types of distortion

• explain the methods of preventing distortion

Weld Stresses- Welding stresses are stresses that exist during and after welding. The latter are called welding

residual stresses. Thus, welding stresses are a special case of thermal stresses.

Distortion

Welding involves highly localized heating of the metal being joined together. The temperature distribution in the

weldment is therefore non uniform. Normally, the weld metal and the heat affected zone (HAZ) are at temperatures

substantially above that of the unaffected base metal. Upon cooling, the weld pool solidifies and shrinks, exerting

stresses on the surrounding weld metal and HAZ.

If the stresses produced from thermal expansion and contraction exceed the yield strength of the parent metal,

localized plastic deformation of the metal occurs. Plastic deformation results in lasting change in the component

dimensions and distorts the structure. This causes distortion of weldments.

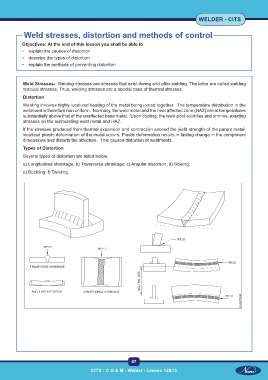

Types of Distortion

Several types of distortion are listed below:

a) Longitudinal shrinkage, b) Transverse shrinkage, c) Angular distortion, d) Bowing,

e) Buckling f) Twisting.

47

CITS : C G & M - Welder - Lesson 12&13 CITS : C G & M - Welder - Lesson 12&13