Page 70 - CITS - Welder - Trade Theory

P. 70

WELDER - CITS

CO and H2 have reducing effect (no oxides are forming) Maximum heat (Hottest point) is just in front of the inner

cone.

One volume of oxygen combines with one volume of acetylene (delivered through the torch) and burns to form.

Two volume of carbon monoxide and one volume of hydrogen plus heat.

Secondary combustion: It takes place in the outer envelope of the flame.

In the outer envelope - secondary burning 2CO + O2 ↑ 2CO2 + Heat

2H2 + O2 ↑ 2H 0O + Heat

Combustion in air (Fig 1): Two volumes of carbon monoxide and 1 volume of hydrogen (Product of primary

combustion) combine with 1.5 volume of oxygen from the surrounding air and burn to form. two volumes of

carbon dioxide and 1 volume of water vapors.

The flame takes an additional 1.5 litres of oxygen from the surrounding atmosphere.(Secondary combustion)

(Fig 1)

Chemical reaction:1 volume of acetylene combines with 2 1/2 volumes of oxygen and burns to form 2 volumes

of carbondioxide and 1 volume of water vapour plus heat.

The product of primary combustion is further burnt in the reducing zone.

The region surrounding the inner cone and it stip is called reducing zone

The reducing zone protects them olten metal from atmospheric effect sasituses the Atmosphere combustion.

oxygen for secondary

Types of oxy - acetylene flames:

The oxy-acetylene gas flame is used for gas welding because

It has a well controlled flame with high temperature

The flame can be easily manipulated for proper melting of the base metal

It does not change the chemical composition of the base metal/weld.

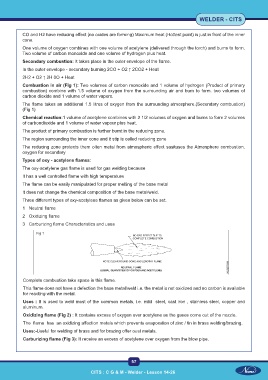

Three different types of oxy-acetylene flames as given below can be set.

1 Neutral flame

2 Oxidizing flame

3 Carburizing flame Characteristics and uses

Fig 1

Complete combustion take space in this flame.

This flame does not have a defection the base metal/weld i.e. the metal is not oxidized and no carbon is available

for reacting with the metal.

Uses : It is used to weld most of the common metals, i.e. mild steel, cast iron , stainless steel, copper and

aluminum.

Oxidizing flame (Fig 2) : It contains excess of oxygen over acetylene as the gases come out of the nozzle.

The flame has an oxidizing affection metals which prevents evaporation of zinc / tin in brass welding/brazing.

Uses:-Useful for welding of brass and for brazing offer oust metals.

Carburizing flame (Fig 3): It receive an excess of acetylene over oxygen from the blow pipe.

57

CITS : C G & M - Welder - Lesson 14-26 CITS : C G & M - Welder - Lesson 14-26