Page 75 - CITS - Welder - Trade Theory

P. 75

WELDER - CITS

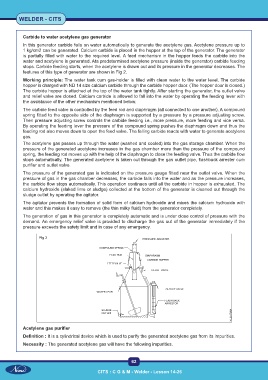

Carbide to water acetylene gas generator

In this generator carbide falls on water automatically to generate the acetylene gas. Acetylene pressure up to

1 kg/cm2 can be generated. Calcium carbide is placed in the hopper at the top of the generator. The generator

is partially filled with water to the required level. A feed mechanism in the hopper feeds the carbide into the

water and acetylene is generated. Ata predetermined acetylene pressure (inside the generator) carbide feeding

stops. Carbide feeding starts, when the acetylene is drawn out and its pressure in the generator decreases. The

features of this type of generator are shown in Fig 2.

Working principle: The water tank cum gas-holder is filled with clean water to the water level. The carbide

hopper is charged with ND 14 size calcium carbide through the carbide hopper door. (The hopper door is closed.)

The carbide hopper is attached at the top of the water tank tightly. After starting the generator, the outlet valve

and relief valve are closed. Calcium carbide is allowed to fall into the water by operating the feeding lever with

the assistance of the other mechanism mentioned below.

The carbide feed valve is controlled by the feed rod and diaphragm (all connected to one another). A compound

spring fitted to the opposite side of the diaphragm is supported by a pressure by a pressure adjusting screw.

Then pressure adjusting screw controls the carbide feeding i.e., more pressure, more feeding and vice versa.

By operating the feeding lever the pressure of the compound spring pushes the diaphragm down and thus the

feeding rod also moves down to open the feed valve. The falling carbide reacts with water to generate acetylene

gas.

The acetylene gas passes up through the water (washed and cooled) into the gas storage chamber. When the

pressure of the generated acetylene increases in the gas chamber more than the pressure of the compound

spring, the feeding rod moves up with the help of the diaphragm to close the feeding valve. Thus the carbide flow

stops automatically. The generated acetylene is taken out through the gas outlet pipe, flashback arrester cum

purifier and outlet valve.

The pressure of the generated gas is indicated on the pressure gauge fitted near the outlet valve. When the

pressure of gas in the gas chamber decreases, the carbide falls into the water and as the pressure increases,

the carbide flow stops automatically. This operation continues until all the carbide in hopper is exhausted. The

calcium hydroxide (slaked lime or sludge) collected at the bottom of the generator is cleaned out through the

sludge outlet by operating the agitator.

The agitator prevents the formation of solid form of calcium hydroxide and mixes the calcium hydroxide with

water and this makes it easy to remove (the thin milky fluid) from the generator completely.

The generation of gas in this generator is completely automatic and is under close control of pressure with the

demand. An emergency relief valve is provided to discharge the gas out of the generator immediately if the

pressure exceeds the safety limit and in case of any emergency.

Fig 2

Acetylene gas purifier

Definition : It is a cylindrical device which is used to purify the generated acetylene gas from its impurities.

Necessity : The generated acetylene gas will have the following impurities.

62

CITS : C G & M - Welder - Lesson 14-26 CITS : C G & M - Welder - Lesson 14-26