Page 74 - CITS - Welder - Trade Theory

P. 74

WELDER - CITS

Methods of acetylene generation: Acetylene is produced in acetylene generators based on two methods.

- Water-to-carbide method

- Carbide-to-water method

In the water-to-carbide method water falls on calcium carbide to produce acetylene. Carbide-to-water means

calcium carbide grains fall on a mass of water producing acetylene. An acetylene generator is a device which

brings proper amounts of calcium carbide and water together to generate the acetylene gas at the required rate.

Acetylene generators are of two types.

- Water-to-carbide type acetylene generator (low pressure)

- Carbide-to-water type acetylene generator (medium pressure).

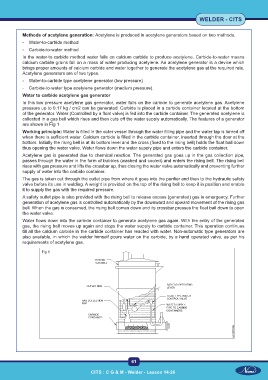

Water to carbide acetylene gas generator

In this low pressure acetylene gas generator, water falls on the carbide to generate acetylene gas. Acetylene

pressure up to 0.17 kg / cm2 can be generated. Carbide is placed in a carbide container located at the bottom

of the generator. Water (Controlled by a float valve) is fed into the carbide container. The generated acetylene is

collected in a gas bell which rises and then cuts off the water supply automatically. The features of a generator

are shown in Fig 1.

Working principle: Water is filled in the outer vessel through the water filling pipe and the water tap is turned off

when there is sufficient water. Calcium carbide is filled in the carbide container, inserted through the door at the

bottom. Initially the rising bell is at its bottom level and the cross (fixed to the rising bell) holds the float ball down

thus opening the water valve. Water flows down the water supply pipe and enters the carbide container.

Acetylene gas is generated due to chemical reaction. The generated gas goes up in the gas collection pipe,

passes through the water in the form of bubbles (washed and cooled) and enters the rising bell. The rising bell

rises with gas pressure and lifts the crossbar up, thus closing the water valve automatically and preventing further

supply of water into the carbide container.

The gas is taken out through the outlet pipe from where it goes into the purifier and then to the hydraulic safety

valve before its use in welding. A weight is provided on the top of the rising bell to keep it in position and enable

it to supply the gas with the required pressure.

A safety outlet pipe is also provided with the rising bell to release excess (generated) gas in emergency. Further

generation of acetylene gas is controlled automatically by the downward and upward movement of the rising gas

bell. When the gas is consumed, the rising bell comes down and its crossbar presses the float ball down to open

the water valve.

Water flows down into the carbide container to generate acetylene gas again. With the entry of the generated

gas, the rising bell moves up again and stops the water supply to carbide container. This operation continues

till all the calcium carbide in the carbide container has reacted with water. Non-automatic type generators are

also available, in which the welder himself pours water on the carbide, by a hand operated valve, as per his

requirements of acetylene gas.

Fig 1

61

CITS : C G & M - Welder - Lesson 14-26 CITS : C G & M - Welder - Lesson 14-26