Page 76 - CITS - Welder - Trade Theory

P. 76

WELDER - CITS

1 Water vapour.

2 Ammonia.

3 Lime dust.

4 Sulphureted hydrogen.

5 Phosphoresced hydrogen.

These impurities, if not removed from the generated acetylene gas, may accur the following harmful

effects:

1 Reduction in flame temperature.

2 Reaction with metal and influencing welding defects like blow holes, porosity etc.

For quality gas welding and cutting acetylene gas used must be free from above impurities. To remove these

impurities from the generated acetylene gas, a suitable gas purifier must be used.

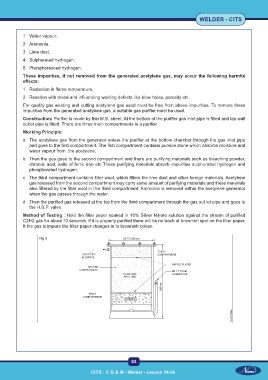

Construction: Purifier is mode by thin M.S. sheet. At the bottom of the purifier gas inlet pipe is fitted and tap wall

outlet pipe is fitted. There are three main compartments in a purifier.

Working Principle:

a The acetylene gas from the generator enters the purifier at the bottom chamber through the gas inlet pipe

and goes to the first comportment. The first compartment contains pumice stone which absorbs moisture and

water vapour from the acetylene.

b Then the gas goes to the second compartment and there are purifying materials such as bleaching powder,

chromic acid, salts of ferric iron etc These purifying materials absorb impurities sulphurated hydrogen and

phosphorated hydrogen.

c The third comportment contains filter wool, which filters the lime dust and other foreign materials. Acetylene

gas released from the second compartment may carry some amount of purifying materials and these materials

also filtered by the filter wool in this third comportment. Ammonia is removed within the acetylene generator

when the gas passes through the water.

d Then the purified gas released at the top from the third compartment through the gas out let pipe and goes to

the H.B.P. valve.

Method of Testing : Hold the filter paper soaked in 10% Silver Nitrate solution against the stream of purified

C2H2 gas for about 10 seconds. If it is properly purified there will be no trach of brownish spot on the filter paper.

It the gas is impure the fiIter paper changes in to brownish colour.

Fig 3

63

CITS : C G & M - Welder - Lesson 14-26 CITS : C G & M - Welder - Lesson 14-26