Page 72 - CITS - Welder - Trade Theory

P. 72

WELDER - CITS

6 It Cac2 is allowed to come into contact with water, it produces Acetylene gas.

7 Powder of Cac2 mixed with borax, it is used as a flux for copper welding.

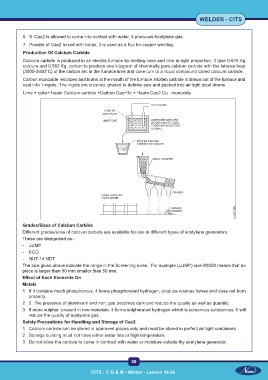

Production Of Calcium Carbide

Calcium carbide is produced in an electric furnace by melting coke and lime in right proportion. It take 0.875 Kg

calcium and 0.562 Kg carbon to produce one kilogram of chemically pure calcium carbide with the intense heat

(3000-3600°C) of the carbon arc in the furnace lime and coke turn to a liquid compound called calcium carbide.

Carbon monoxide escapes and burns at the mouth of the furnace. Molten carbide is drawn out of the furnace and

cast into ↑ ingots. The ingots are crushed, graded to definite size and packed into air tight steel drums

Lime + coke+ heat= Calcium carbide +Carbon Cao+3c + Heat= Cac2 Co monoxide.

Grades/Sizes of Calcium Carbide

Different grades/sires of calcium carbide are available for use in different types of acetylane generators.

These are designated as:-

- LUMP

- EGG

- NUT-14 NDT

The size given above indicate the range in the Screening sizes. For example (LUMP) size 90X50 means that no

piece is larger than 90 mm smaller than 50 mm.

Effect of Each Elements On

Metals

1 If it contains much phosphorous, it forms phasphorated hydrogen, produce noxious fumes and does not born

properly.

2 2. The presence of aluminium and iron, gas becomes dark and reduce the quality as well as quantity.

3 If more sulphur present in row materials, it forms sulphurated hydrogen which is poisonous substances. It will

reduce the quality of acetylene gas.

Safety Precautions for Handling and Storage of Cac2

1 Calcium carbide can be stored in approved places only and must be stored in perfect air tight containers.

2 Storage building must not have either water line or high temperature.

3 Do not allow the carbide to come in contract with water or moisture outside thy acetylene generator.

59

CITS : C G & M - Welder - Lesson 14-26 CITS : C G & M - Welder - Lesson 14-26