Page 163 - CITS - Dress Making - TT - 2024

P. 163

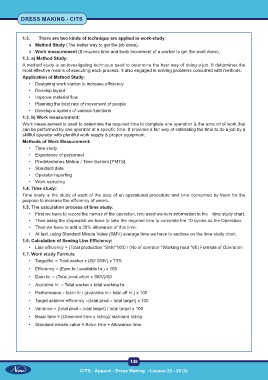

DRESS MAKING - CITS

1.3. There are two kinds of technique are applied in work-study:

a Method Study (The better way to get the job done).

b Work measurement (It requires time and body movement of a worker to get the work done).

1.3. a) Method Study:

A method study is an investigating technique used to determine the best way of doing a job. It determines the

most effective means of executing each process. It also engaged in solving problems concurred with methods.

Application of Method Study:

• Designing work station to increase efficiency

• Develop layout

• Improve material flow

• Planning the best rate of movement of people

• Develop a system of various functions

1.3. b) Work measurement:

Work measurement is used to determine the required time to complete one operation & the amount of work that

can be performed by one operator at a specific time. It provides a fair way of estimating the time to do a job by a

skillful operator with plentiful work supply & proper equipment.

Methods of Work Measurement:

• Time study

• Experience of personnel

• Predetermines Motion / Time System [PMTS]

• Standard data

• Operator reporting

• Work sampling

1.4. Time study:

Time study is the study of each of the step of an operational procedure and time consumed by them for the

purpose to increase the efficiency of wears.

1.5. The calculation process of time study:

• First we have to record the names of the operation, m/c used workers information in the time study chart.

• Then using the stopwatch we have to take the required time to complete the 10 cycles as the Operation.

• Then we have to add a 30% allowance of this time.

• At last, using Standard Minute Value (SMV) average time we have to enclose on the time study chart.

1.6. Calculation of Sewing Line Efficiency:

• Line efficiency = (Total production *SMV*100) / (No of operator *Working hour *60) Formula of Operation

1.7. Work study Formula

• Target/hr. = Total worker x (60/ SMV) x 73%

• Efficiency = (Earn hr./ available hr.) x 100

• Earn hr. = (Total production x SMV)/60

• Available hr. = Total worker x total working hr.

• Performance = Earn hr./ (available hr.- total off hr.) x 100

• Target achieve efficiency =(total prod – total target) x 100

• Variance = (total prod – total target) / total target x 100

• Basic time = (Observed time x rating)/ standard rating

• Standard minute value = Basic time + Allowance time

148

CITS : Apparel - Dress Making - Lesson 22 - 29 (3)