Page 116 - CTS - Dress Making - TP - Volume - 1

P. 116

DRESS MAKING - CITS

Holes are typically treated as a major defect in the fabric and are assigned either two or four penalty points during

fabric inspection, depending on their size.

Causes

Holes are usually caused by an accidental cut or tear to the fabric. Broken needles or rough mechanical parts are

common culprits for fabric tearing during manufacturing.

Prevention: Prevent future holes by ensuring your supplier has procedures in place to regularly check needles

and machinery prior to production.

13. Defective Selvage (Cut, Waved Or Creased)

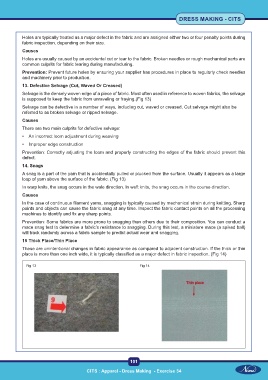

Selvage is the densely woven edge of a piece of fabric. Most often used in reference to woven fabrics, the selvage

is supposed to keep the fabric from unraveling or fraying.(Fig 13)

Selvage can be defective in a number of ways, including cut, waved or creased. Cut selvage might also be

referred to as broken selvage or ripped selvage.

Causes

There are two main culprits for defective selvage:

• An incorrect loom adjustment during weaving

• Improper edge construction

Prevention: Correctly adjusting the loom and properly constructing the edges of the fabric should prevent this

defect.

14. Snags

A snag is a part of the yarn that is accidentally pulled or plucked from the surface. Usually it appears as a large

loop of yarn above the surface of the fabric. (Fig 13)

In warp knits, the snag occurs in the wale direction. In weft knits, the snag occurs in the course direction.

Causes

In the case of continuous filament yarns, snagging is typically caused by mechanical strain during knitting. Sharp

points and objects can cause the fabric snag at any time. Inspect the fabric contact points on all the processing

machines to identify and fix any sharp points.

Prevention: Some fabrics are more prone to snagging than others due to their composition. You can conduct a

mace snag test to determine a fabric’s resistance to snagging. During this test, a miniature mace (a spiked ball)

will track randomly across a fabric sample to predict actual wear and snagging.

15 Thick Place/Thin Place

These are unintentional changes in fabric appearance as compared to adjacent construction. If the thick or thin

place is more than one inch wide, it is typically classified as a major defect in fabric inspection. (Fig 14)

Fig 13 Fig 14

101

CITS : Apparel - Dress Making - Exercise 34