Page 140 - CITS - ED - Mechanical

P. 140

ENGINEERING DRAWING - CITS

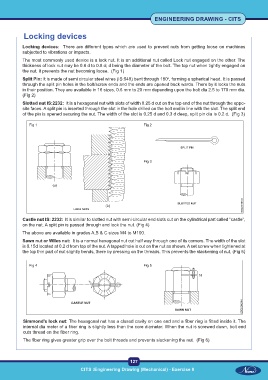

Locking devices

Locking devices: There are different types which are used to prevent nuts from getting loose on machines

subjected to vibrations or impacts.

The most commonly used device is a lock nut. It is an additional nut called Lock nut engaged on the other. The

thickness of lock nut may be 0.6 d to 0.8 d; d being the diameter of the bolt. The top nut when tightly engaged on

the nut, it prevents the nut becoming loose. (Fig 1)

Split Pin: It is made of semi circular steel wires (IS:549) bent through 180 , forming a spherical head. It is passed

o

through the split pin holes in the bolt/screw ends and the ends are opened back wards. There by it locks the nuts

in their position. They are available in 16 sizes, 0.6 mm to 20 mm depending upon the bolt dia 2.5 to 170 mm dia.

(Fig 2)

Slotted nut IS:2232: It is a hexagonal nut with slots of width 0.25 d cut on the top end of the nut through the oppo-

site faces. A split pin is inserted through the slot in the hole drilled on the bolt end in line with the slot. The split end

of the pin is opened securing the nut. The width of the slot is 0.25 d and 0.3 d deep, split pin dia is 0.2 d. (Fig 3)

Fig 1 Fig 2

Fig 3

Castle nut IS: 2232: It is similar to slotted nut with semi circular end slots cut on the cylindrical part called “castle”,

on the nut. A split pin is passed through and lock the nut. (Fig 4)

The above are available in grades A,B & C sizes M4 to M100.

Sawn nut or Wiles nut: It is a normal hexagonal nut cut half way through one of its corners. The width of the slot

is 0.15d located at 0.2 d from top of the nut. A tapped hole is cut on the nut as shown. A set screw when tightened at

the top thin part of nut slightly bends, there by pressing on the threads. This prevents the slackening of nut. (Fig 5)

Fig 4 Fig 5

Simmond’s lock nut: The hexagonal nut has a closed cavity on one end and a fiber ring is fitted inside it. The

internal dia meter of a fiber ring is slightly less than the core diameter. When the nut is screwed down, bolt end

cuts thread on the fiber ring.

The fiber ring gives greater grip over the bolt threads and prevents slackening the nut. (Fig 6)

127

CITS :Engineering Drawing (Mechanical) - Exercise 8