Page 141 - CITS - ED - Mechanical

P. 141

ENGINEERING DRAWING - CITS

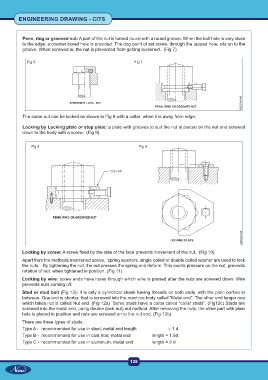

Penn, ring or grooved nut: A part of the nut is turned round with a round groove. When the bolt hole is very close

to the edge, a counter bored hole is provided. The dog point of set screw, through the tapped hole, sits on to the

groove. When screwed in, the nut is prevented from getting loosened. (Fig 7)

Fig 6 Fig 7

The same nut can be locked as shown in Fig 8 with a collar when it is away from edge.

Locking by Locking plate or stop plate: a plate with grooves to suit the nut is placed on the nut and screwed

down to the body with a screw. (Fig 9)

Fig 8 Fig 9

Locking by screw: A screw fixed by the side of the face prevents movement of the nut. (Fig 10)

Apart from the methods mentioned above, spring washers, single coiled or double coiled washer are used to lock

the nuts. By tightening the nut, the nut presses the spring and deform. This exerts pressure on the nut, prevents

rotation of nut, when tightened in position. (Fig 11)

Locking by wire: screw ends have holes through which wire is passed after the nuts are screwed down. Wire

prevents nuts coming off.

Stud or stud bolt (Fig 12): It is only a cylindrical shank having threads on both ends, with the plain portion in

between. One end is shorter, that is screwed into the machine body called “Metal end”. The other end longer one

which takes nut is called Nut end. (Fig 12a) Some studs have a collar called “collar studs”. (Fig12c) Studs are

screwed into the metal end, using double (lock nut) nut method. After removing the nuts, the other part with plain

hole is placed in position and nuts are screwed on to the nut end. (Fig 12b)

There are three types of studs:

Type A - recommended for use in steel; metal end length = 1 d.

Type B - recommended for use in cast iron; metal end length = 1.5d.

Type C - recommended for use in aluminum, metal end length = 2 d

128