Page 166 - CITS - ED - Mechanical

P. 166

ENGINEERING DRAWING - CITS

Keys

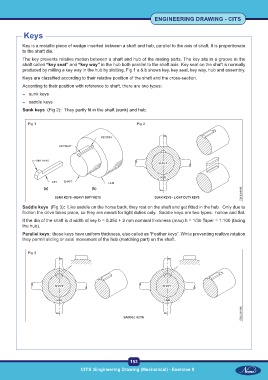

Key is a metallic piece of wedge inserted between a shaft and hub, parallel to the axis of shaft. It is proportionate

to the shaft dia.

The key prevents relative motion between a shaft and hub of the mating parts. The key sits in a groove in the

shaft called “key seat” and “key way” in the hub both parallel to the shaft axis. Key seat on the shaft is normally

produced by milling a key way in the hub by slotting. Fig 1 a & b shows key, key seat, key way, hub and assembly.

Keys are classified according to their relative position of the shaft and the cross-section.

According to their position with reference to shaft, there are two types:

– sunk keys

– saddle keys

Sunk keys (Fig 2): They partly fit in the shaft (sunk) and hub.

Fig 1 Fig 2

Saddle keys (Fig 3): Like saddle on the horse back, they rest on the shaft and get fitted in the hub. Only due to

friction the drive takes place, so they are meant for light duties only. Saddle keys are two types: hollow and flat.

If the dia of the shaft is d width of key b = 0.25d + 2 mm nominal thickness (max) h = 1/3b Taper = 1:100 (facing

the hub).

Parallel keys: these keys have uniform thickness, also called as “Feather keys”. While preventing realtive rotation

they permit sliding or axial movement of the hub (matching part) on the shaft.

Fig 3

153

CITS :Engineering Drawing (Mechanical) - Exercise 8 CITS :Engineering Drawing (Mechanical) - Exercise 8