Page 167 - CITS - ED - Mechanical

P. 167

ENGINEERING DRAWING - CITS

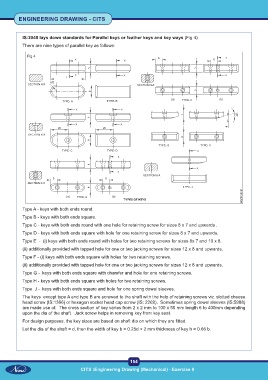

IS:2048 lays down standards for Parallel keys or feather keys and key ways (Fig 4)

There are nine types of parallel key as follows:

Fig 4

Type A - keys with both ends round.

Type B - keys with both ends square.

Type C - keys with both ends round with one hole for retaining screw for sizes 8 x 7 and upwards .

Type D - keys with both ends square with hole for one retaining screw for sizes 8 x 7 and upwards.

Type E - (i) keys with both ends round with holes for two retaining screws for sizes 8x 7 and 10 x 8.

(ii) additionally provided with tapped hole for one or two jacking screws for sizes 12 x 8 and upwards.

Type F - (i) keys with both ends square with holes for two retaining screws.

(ii) additionally provided with tapped hole for one or two jacking screws for sizes 12 x 8 and upwards.

Type G - keys with both ends square with chamfer and hole for one retaining screws.

Type H - keys with both ends square with holes for two retaining screws.

Type J - keys with both ends square and hole for one spring dowel sleeves.

The keys except type A and type B are screwed to the shaft with the help of retaining screws viz. slotted cheese

head screw (IS:1366) or hexagon socket head cap screw (IS: 2269). Sometimes spring dowel sleeves (IS:5988)

are made use of. The cross section of key varies from 2 x 2 mm to 100 x 50 mm length 6 to 400mm depending

upon the dia of the shaft. Jack screw helps in removing key from key seat.

For design purposes, the key sizes are based on shaft dia on which they are fitted.

Let the dia of the shaft = d, then the width of key b = 0.25d + 2 mm thickness of key h = 0.66 b.

154

CITS :Engineering Drawing (Mechanical) - Exercise 8