Page 169 - CITS - ED - Mechanical

P. 169

ENGINEERING DRAWING - CITS

Fig 5 Fig 6

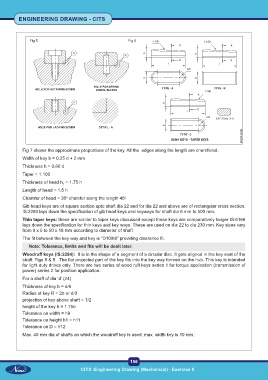

Fig 7 shows the approximate proportions of the key. All the edges along the length are chamfered.

Width of key b = 0.25 d + 2 mm

Thickness h = 0.66 d

Taper = 1:100

Thickness of head h = 1.75 h

1

Length of head = 1.5 h

Chamfer of head = 30 chamfer along the length 45 o

o

Gib head keys are of square section upto shaft dia 22 and for dia 22 and above are of rectangular cross section.

IS:2293 lays down the specification of gib head keys and keyways for shaft dia 6 mm to 500 mm.

Thin taper keys: these are similar to taper keys discussed except these keys are comparatively longer IS:6166

lays down the specification for thin keys and key ways. These are used on dia 22 to dia 230 mm. Key sizes vary

from 8 x 5 to 50 x 18 mm according to diameter of shaft

The fit between the key way and key is “D10/h9” providing clearance fit.

Note: Tolerance, limits and fits will be dealt later.

Woodruff keys (IS:2294): It is in the shape of a segment of a circular disc. It gets aligned in the key seat of the

shaft. Figs 8 & 9. The flat projected part of the key fits into the key way formed on the hub. This key is intended

for light duty drives only. There are two series of wood ruft keys series 1 for torque application (transmission of

power) series 2 for position application.

For a shaft of dia ‘d’ (24)

Thickness of key b = d/6

Radius of key R = 2b or d/3

projection of key above shaft = T/2

height of the key h = 1.75b

Tolerance on width = h9

Tolerance on height h1 = h11

Tolerance on D = h12

Max. 40 mm dia of shafts on which the woodruff key is used; max. width key is 10 mm.

156

CITS :Engineering Drawing (Mechanical) - Exercise 8