Page 174 - CITS - ED - Mechanical

P. 174

ENGINEERING DRAWING - CITS

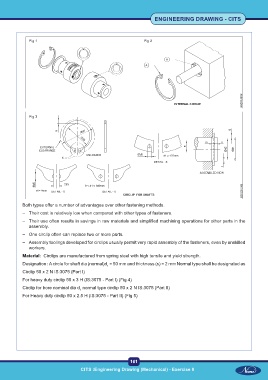

Fig 1 Fig 2

Fig 3

Both types offer a number of advantages over other fastening methods.

– Their cost is relatively low when compared with other types of fasteners.

– Their use often results in savings in raw materials and simplified machining operations for other parts in the

assembly.

– One circlip often can replace two or more parts.

– Assembly toolings developed for circlips usually permit very rapid assembly of the fasteners, even by unskilled

workers.

Material: Circlips are manufactured from spring steel with high tensile and yield strength.

Designation : A circle for shaft dia (normal)d = 50 mm and thickness (s) = 2 mm Normal type shall be designated as

1

Circlip 50 x 2 N IS:3075 (Part I)

For heavy duty circlip 50 x 3 H (IS:3075 - Part I) (Fig 4)

Circlip for bore nominal dia d normal type circlip 50 x 2 N IS:3075 (Part II)

1

For Heavy duty circlip 50 x 2.5 H (IS:3075 - Part II) (Fig 5)

161

CITS :Engineering Drawing (Mechanical) - Exercise 8 CITS :Engineering Drawing (Mechanical) - Exercise 8