Page 175 - CITS - ED - Mechanical

P. 175

ENGINEERING DRAWING - CITS

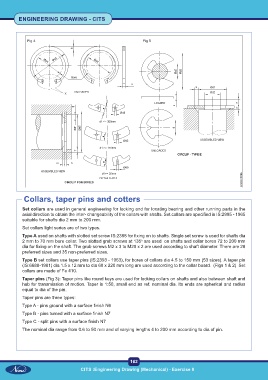

Fig 4 Fig 5

Collars, taper pins and cotters

Set collars are used in general engineering for locking and for locating bearing and other running parts in the

axial direction to obtain the inter- changeability of the collars with shafts. Set collars are specified in IS:2995 - 1965

suitable for shafts dia 2 mm to 200 mm.

Set collars light series are of two types.

Type A used on shafts with slotted set screw IS:2388 for fixing on to shafts. Single set screw is used for shafts dia

2 mm to 70 mm bore collar. Two slotted grub screws at 135 are used on shafts and collar bores 72 to 200 mm

o

dia for fixing on the shaft. The grub screws M2 x 3 to M20 x 2 are used according to shaft diameter. There are 28

preferred sizes and 35 non-preferred sizes.

Type B set collars use taper pins (IS:2393 - 1963), for bores of collars dia 4.5 to 150 mm (53 sizes). A taper pin

(IS:6688-1981) dia 1.5 x 12 mm to dia 60 x 220 mm long are used according to the collar board. (Figs 1 & 2) Set

collars are made of Fe 410.

Taper pins (Fig 3): Taper pins like round keys are used for locking collars on shafts and also between shaft and

hub for transmission of motion. Taper is 1:50, small end as ref. nominal dia. Its ends are spherical and radius

equal to dia of the pin.

Taper pins are three types:

Type A - pins ground with a surface finish N6

Type B - pins turned with a surface finish N7

Type C - split pins with a surface finish N7

The nominal dia range from 0.6 to 50 mm and of varying lengths 4 to 200 mm according to dia of pin.

162

CITS :Engineering Drawing (Mechanical) - Exercise 8