Page 177 - CITS - ED - Mechanical

P. 177

ENGINEERING DRAWING - CITS

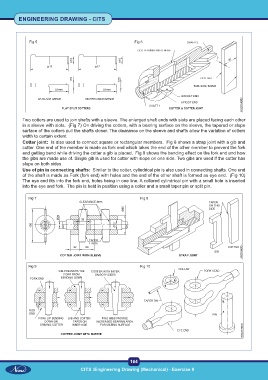

Fig 5 Fig 6

Two cotters are used to join shafts with a sleeve. The enlarged shaft ends with slots are placed facing each other

in a sleeve with slots. (Fig 7) On driving the cotters, with a bearing surface on the sleeve, the tapered or slope

surface of the cotters pull the shafts closer. The clearance on the sleeve and shafts allow the variation of cotters

width to certain extent.

Cotter joint: Is also used to connect square or rectangular members. Fig 8 shows a strap joint with a gib and

cotter. One end of the member is made as fork end which takes the end of the other member to prevent the fork

end getting bend while driving the cotter a gib is placed. Fig 9 shows the bending effect on the fork end and how

the gibs are made use of. Single gib is used for cotter with slope on one side. Two gibs are used if the cotter has

slope on both sides.

Use of pin in connecting shafts: Similar to the cotter, cylindrical pin is also used in connecting shafts. One end

of the shaft is made as Fork (fork end) with holes and the end of the other shaft is formed as eye end. (Fig 10)

The eye end fits into the fork end, holes being in one line. A collared cylindrical pin with a small hole is inserted

into the eye and fork. The pin is held in position using a coller and a small taper pin or split pin.

Fig 7 Fig 8

Fig 9 Fig 10

164

CITS :Engineering Drawing (Mechanical) - Exercise 8