Page 226 - Electrician - TT (Volume 1)

P. 226

ELECTRICIAN - CITS

Not used where load may be removed

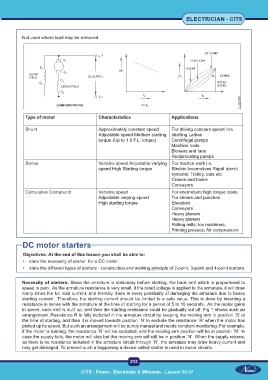

Type of motor Characteristics Applications

Shunt Approximately constant speed For driving constant speed line

Adjustable speed Medium starting shafting Lathes

torque (Up to 1.5 F.L. torque) Centrifugal pumps

Machine tools

Blowers and fans

Reciprocating pumps

Series Variable speed Adjustable variying For traction work i.e.

speed High Starting torque Electric locomotives Rapid transit

systems. Trolley, cars etc.

Cranes and hoists

Conveyors

Comulative Compound Variable speed For intermittent high torque loads

Adjustable varying speed For shears and punches

High starting torque Elevators

Conveyors

Heavy planers

Heavy planers

Rolling mills; Ice machines;

Printing presses; Air compressors

DC motor starters

Objectives: At the end of this lesson you shall be able to:

• state the necessity of starter for a DC motor

• state the different types of starters - construction and working principle of 2-point, 3-point and 4-point starters.

Necessity of starters: Since the armature is stationary before starting, the back emf which is proportional to

speed is zero. As the armature resistance is very small, if the rated voltage is applied to the armature, it will draw

many times the full load current, and thereby, there is every possibility of damaging the armature due to heavy

starting current. Therefore, the starting current should be limited to a safe value. This is done by inserting a

resistance in series with the armature at the time of starting for a period of 5 to 10 seconds. As the motor gains

in speed, back emf is built up, and then the starting resistance could be gradually cut off. Fig 1 shows such an

arrangement. Resistance R is fully included in the armature circuit by keeping the moving arm in position `S’ at

the time of starting, and then it is moved towards position `N’ to exclude the resistance `R’ when the motor has

picked up its speed. But such an arrangement will be purely manual and needs constant monitoring. For example,

if the motor is running, the resistance `R’ will be excluded, and the moving arm position will be at position `N’. In

case the supply fails, the motor will stop but the moving arm will still be in position `N’. When the supply returns,

as there is no resistance included in the armature circuit through `R’, the armature may draw heavy current and

may get damaged. To prevent such a happening a device called starter is used in motor circuits.

213

CITS : Power - Electrician & Wireman - Lesson 30-37 CITS : Power - Electrician & Wireman - Lesson 30-37