Page 337 - Electrician - TT (Volume 2)

P. 337

ELECTRICIAN - CITS

But in the case of heavy loads; say some hundreds, of ampere are flowing in a circuit the resultant spark at

contact are heavy and this leads to electrical fire. To overcome this problem the sparks at the contacts are to

be controlled or quenched, when any load makes or breaks. The equipment or device used to make or break a

circuit under control at the same time it prevents or quenching the resultant fire is called as a circuit breaker. The

breakers are named after the quenching medium used to control the fire such (1) air circuit breaker, (2) oil circuit

breaker, (3) vaccum circuit breaker and (4) Sulphur hexafluoride (SF6) circuit breaker.

Air circuit breaker (ACB): A circuit breaker which uses the either natural air or blast air as an Arc quenching

medium is termed as Air-circuit breakers.

ACB is widely used upto 15KV in place of oil circuit breaker because there is no chance of the fire due to the

quenching oil as in case of OCB.

Air- Circuit breakers are widely used in industries as well as power system for controlling and protection of

different section of the circuit like, Transformers, Motors, Generators / Alternator etc and leads the system stable

and reliable. Other components are also associated with circuit breakers like fuses, relays, switches etc.

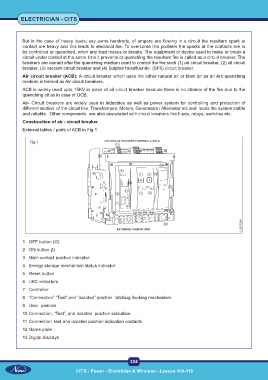

Construction of air - circuit breaker

External lables / parts of ACB in Fig 1

Fig 1

1 OFF button (O)

2 ON button (I)

3 Main contact position indicator

4 Energy storage mechanism status indicator

5 Reset button

6 LED indicators

7 Controller

8 “Connection” “Test” and “isolated” position latching /locking mechanism

9 User padlock

10 Connection, “Test”, and isolated position indication

11 Connection test and isolated position indication contacts

12 Name plate

13 Digital displays

324

CITS : Power - Electrician & Wireman - Lesson 106-116