Page 211 - CITS - Fashion Design Technology - Trade Theory

P. 211

FASHION DESIGN & TECHNOLOGY - CITS

Trouser pressing

Trousers include a wide variety of garments, ranging from jeans, women’s trousers with simpler construction and

requiring a less sharp crease, men’s trousers including four pockets, and suit trousers. The trouser pressing is

carried out in two operations along with under pressing of the seam. The first operation is done for legging on a

flat press to set and crease the legs and the second operation for topping in a series of lays around the top of the

trouser on a contoured press.

Double legger-pressing machine

Double legger-pressing machine is used for pressing trousers, and in this machine both the legs are pressed

simultaneously with the top hanging down between two separate bucks. These machines consist of vertically

acting heads, carousels and microprocessor controls. Heat resistant silicone foam is used for covering bucks

of steam presses and tables used with irons and vacuum boards and the outside being covered with a woven

polyester cover. Sometimes stretch nylon is used with the highly contoured bucks.

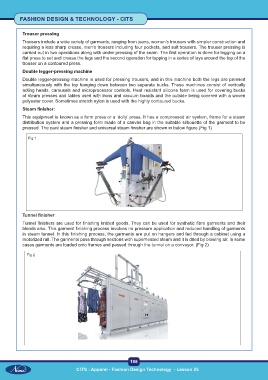

Steam finisher:

This equipment is known as a form press or a ‘dolly’ press. It has a compressed air system, frame for a steam

distribution system and a pressing form made of a canvas bag in the suitable silhouette of the garment to be

pressed. The pant steam finisher and universal steam finisher are shown in below figure.(Fig 1)

Fig 1

Tunnel finisher

Tunnel finishers are used for finishing knitted goods. They can be used for synthetic fibre garments and their

blends also. This garment finishing process involves no pressure application and reduced handling of garments

in steam tunnel. In this finishing process, the garments are put on hangers and fed through a cabinet using a

motorized rail. The garments pass through sections with superheated steam and it is dried by blowing air. In some

cases garments are loaded onto frames and passed through the tunnel on a conveyor. (Fig 2)

Fig 2

198

CITS : Apparel - Fashion Design Technology - Lesson 25