Page 221 - CITS - Fashion Design Technology - Trade Theory

P. 221

FASHION DESIGN & TECHNOLOGY - CITS

attract customers faster and easily. On the other hand, they create a show room of their product to attract the

buyer. Moreover, this house maintain the merchandiser to follow up the product processing line perfectly and also

build a quality assurance team for checking the actual quality of the product.

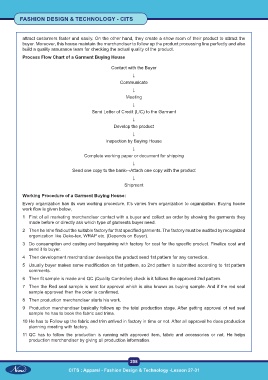

Process Flow Chart of a Garment Buying House

Contact with the Buyer

↓

Communicate

↓

Meeting

↓

Send Letter of Credit (L/C) to the Garment

↓

Develop the product

↓

Inspection by Buying House

↓

Complete working paper or document for shipping

↓

Send one copy to the bank↔Attach one copy with the product

↓

Shipment

Working Procedure of a Garment Buying House:

Every organization has its own working procedure. It’s varies from organization to organization. Buying house

work flow is given below,

1 First of all marketing merchandiser contact with a buyer and collect an order by showing the garments they

made before or directly ask which type of garments buyer need.

2 Then he /she find out the suitable factory for that specified garments. The factory must be audited by recognized

organization like Oeko-tex, WRAP etc. (Depends on Buyer).

3 Do consumption and costing and bargaining with factory for cost for the specific product. Finalize cost and

send it to buyer.

4 Then development merchandiser develops the product send 1st pattern for any correction.

5 Usually buyer makes some modification on 1st pattern, so 2nd pattern is submitted according to 1st pattern

comments.

6 Then fit sample is made and QC (Quality Controller) check is it follows the approved 2nd pattern.

7 Then the Red seal sample is sent for approval which is also known as buying sample. And if the red seal

sample approved then the order is confirmed.

8 Then production merchandiser starts his work.

9 Production merchandiser basically follows up the total production stage. After getting approval of red seal

sample he has to book the fabric and trims.

10 He has to Follow up the fabric and trim arrived in factory in time or not. After all approval he does production

planning meeting with factory.

11 QC has to follow the production is running with approved item, fabric and accessories or not. He helps

production merchandiser by giving all production information.

208

CITS : Apparel - Fashion Design & Technology -Lesson 27-31