Page 182 - CITS - Fitter Trade Practical - Volume -2

P. 182

FITTER - CITS

Job Sequence

Disassembly

• Disconnect air and electrical connections to the cylinder assembly and remove the cylinder from machine.

• Remove and retain air lines and any other accessory items(solenoid valve, flow controls, etc.) from the cylinder

assembly.

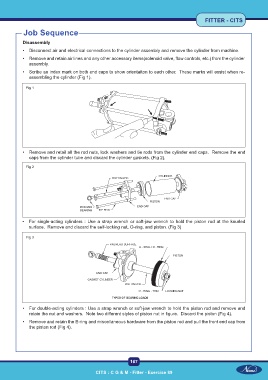

• Scribe an index mark on both end caps to show orientaiton to each other. These marks will assist when re-

assembling the cylinder (Fig 1).

Fig 1

• Remove and retail all the rod nuts, lock washers and tie rods from the cylinder end caps. Remove the end

caps from the cylinder tube and discard the cylinder gaskets. (Fig 2).

Fig 2

• For single-acting cylinders : Use a strap wrench or soft-jaw wrench to hold the piston rod at the knurled

surface. Remove and discard the self-locking nut, O-ring, and piston. (Fig 3)

Fig 3

• For double-acting cylinders : Use a strap wrench or soft-jaw wrench to hold the piston rod and remove and

retain the nut and washers. Note two different styles of piston nut in figure. Discard the piston (Fig 4).

• Remove and retain the E-ring and miscellaneous hardware from the piston rod and pull the front end cap from

the piston rod (Fig 4).

167

CITS : C G & M - Fitter - Exercise 89