Page 227 - CITS - Fitter Trade Practical - Volume -2

P. 227

FITTER - CITS

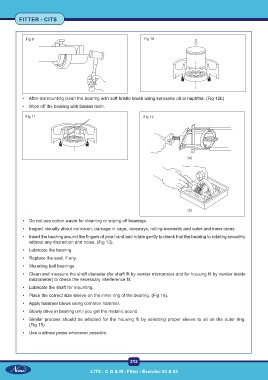

Fig 9 Fig 10

• After dismounting clean the bearing with soft bristle brush using kerosene oil or naphtha. (Fig 12b)

• Wipe off the bearing with banian cloth.

Fig 11 Fig 12

• Do not use cotton waste for cleaning or wiping off bearings.

• Inspect visually about corrosion, damage in cage, raceways, rolling elements and outer and inner races.

• Insert the bearing around the fingers of your hand and rotate gently to check that the bearing to rotating smoothly

without any distraction and noise. (Fig 13).

• Lubricate the bearing.

• Replace the seal, if any.

• Mounting ball bearings

• Clean and measure the shaft diameter (for shaft fit by vernier micrometer and for housing fit by vernier inside

micrometer) to check the necessary interference fit.

• Lubricate the shaft for mounting.

• Place the correct size sleeve on the inner ring of the bearing. (Fig 14).

• Apply hammer blows using common hammer.

• Slowly drive in bearing until you get the metallic sound.

• Similar process should be adopted for the housing fit by selecting proper sleeve to sit on the outer ring.

(Fig 15)

• Use a arbour press whenever possible.

212

CITS : C G & M - Fitter - Exercise 92 & 93