Page 224 - CITS - Fitter Trade Practical - Volume -2

P. 224

FITTER - CITS

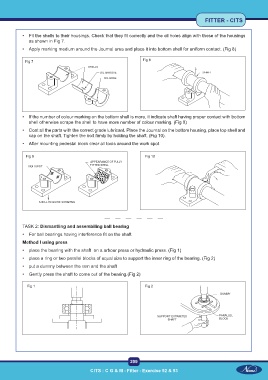

• Fit the shells to their housings. Check that they fit correctly and the oil holes align with those of the housings

as shown in Fig 7.

• Apply marking medium around the Journal area and place it into bottom shell for uniform contact. (Fig 8)

Fig 7 Fig 8

• If the number of colour marking on the bottom shell is more, it indicate shaft having proper contact with bottom

shell otherwise scrape the shell to have more number of colour marking. (Fig 9)

• Coat all the parts with the correct grade lubricant. Place the Journal on the bottom housing, place top shell and

cap on the shaft. Tighten the bolt firmly by holding the shaft. (Fig 10).

• After mounting pedestal block clear all tools around the work spot.

Fig 9 Fig 10

TASK 2: Dismantling and assembiling ball bearing

• For ball bearings having interference fit on the shaft

Method I using press

• place the bearing with the shaft on a arbour press or hydraulic press. (Fig 1)

• place a ring or two parallel blocks of equal size to support the inner ring of the bearing. (Fig 2)

• put a dummy between the ram and the shaft

• Gently press the shaft to come out of the bearing.(Fig 2)

Fig 1 Fig 2

209

CITS : C G & M - Fitter - Exercise 92 & 93