Page 223 - CITS - Fitter Trade Practical - Volume -2

P. 223

FITTER - CITS

Job Sequence

TASK 1: Dismatling and assembiling bush bearing

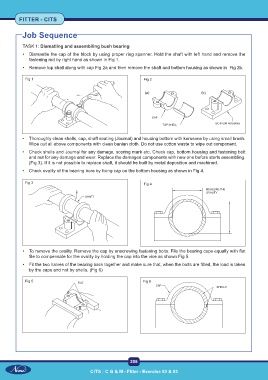

• Dismantle the cap of the block by using proper ring spanner. Hold the shaft with left hand and remove the

fastening nut by right hand as shown in Fig 1.

• Remove top shall along with cap Fig 2a and then remove the shaft and bottom housing as shown in Fig 2b.

Fig 1 Fig 2

• Thoroughly clean shells, cap, shaft seating (Journal) and housing bottom with kerosene by using small brush.

Wipe out all above components with clean banian cloth. Do not use cotton waste to wipe out component.

• Check shells and Journal for any damage, scoring mark etc. Check cap, bottom housing and fastening bolt

and nut for any damage and wear. Replace the damaged components with new one before starts assembling.

(Fig 3). If it is not possible to replace shaft, it should be built by metal deposition and machined.

• Check ovality of the bearing bore by fixing cap on the bottom housing as shown in Fig 4.

Fig 3 Fig 4

• To remove the ovality. Remove the cap by unscrewing fastening bolts. File the bearing caps equally with flat

file to compensate for the ovality by holding the cap into the vice as shown Fig 5.

• Fit the two halves of the bearing back together and make sure that, when the bolts are fitted, the load is taken

by the caps and not by shells. (Fig 6)

Fig 5 Fig 6

208

CITS : C G & M - Fitter - Exercise 92 & 93