Page 219 - CITS - Fitter Trade Practical - Volume -2

P. 219

FITTER - CITS

Fig 2

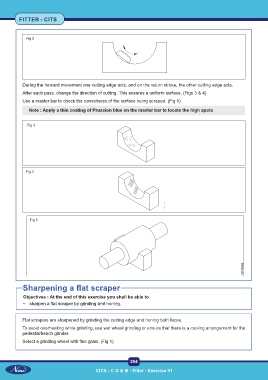

During the forward movement one cutting edge acts, and on the return stroke, the other cutting edge acts.

After each pass, change the direction of cutting. This ensures a uniform surface. (Figs 3 & 4)

Use a master bar to check the correctness of the surface being scraped. (Fig 5)

Note : Apply a thin coating of Prussion blue on the master bar to locate the high spots

Fig 3

Fig 4

Fig 5

Sharpening a flat scraper

Objectives : At the end of this exercise you shall be able to

• sharpen a flat scraper by grinding and honing.

Flat scrapers are sharpened by grinding the cutting edge and honing both faces.

To avoid overheating while grinding, use wet wheel grinding or ensure that there is a cooling arrangement for the

pedestal/bench grinder.

Select a grinding wheel with fine grain. (Fig 1)

204

CITS : C G & M - Fitter - Exercise 91