Page 220 - CITS - Fitter Trade Practical - Volume -2

P. 220

FITTER - CITS

Soft grade aluminium oxide grinding wheel with large diameter gives best results.

Note :Check for gap between the work-rest and the grinding wheel, and adjust, if necessary.

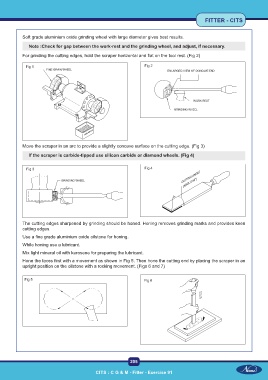

For grinding the cutting edges, hold the scraper horizontal and flat on the tool rest. (Fig 2)

Fig 1 Fig 2

Move the scraper in an arc to provide a slightly concave surface on the cutting edge. (Fig 3)

If the scraper is carbide-tipped use silicon carbide or diamond wheels. (Fig 4)

Fig 3 Fig 4

The cutting edges sharpened by grinding should be honed. Honing removes grinding marks and provides keen

cutting edges.

Use a fine grade aluminium oxide oilstone for honing.

While honing use a lubricant.

Mix light mineral oil with kerosene for preparing the lubricant.

Hone the faces first with a movement as shown in Fig 5. Then hone the cutting end by placing the scraper in an

upright position on the oilstone with a rocking movement. (Figs 6 and 7)

Fig 5 Fig 6

205

CITS : C G & M - Fitter - Exercise 91