Page 56 - CITS - Fitter Trade Practical - Volume -2

P. 56

FITTER - CITS

Internal threading blind holes using hand taps holes)

Objectives: At the end of this exercise you shall be able to

• cut internal threads using hand taps.

Drilling a blind hole

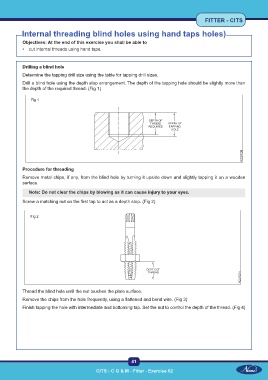

Determine the tapping drill size using the table for tapping drill sizes.

Drill a blind hole using the depth stop arrangement. The depth of the tapping hole should be slightly more than

the depth of the required thread. (Fig 1)

Fig 1

Procedure for threading

Remove metal chips, if any, from the blind hole by turning it upside down and slightly tapping it on a wooden

surface.

Note: Do not clear the chips by blowing as it can cause injury to your eyes.

Screw a matching nut on the first tap to act as a depth stop. (Fig 2)

Fig 2

Thread the blind hole until the nut touches the plate surface.

Remove the chips from the hole frequently, using a flattened and bend wire. (Fig 3)

Finish tapping the hole with intermediate and bottoming tap. Set the nut to control the depth of the thread. (Fig 4)

41

CITS : C G & M - Fitter - Exercise 62