Page 58 - CITS - Fitter Trade Practical - Volume -2

P. 58

FITTER - CITS

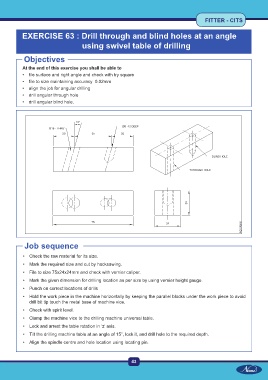

EXERCISE 63 : Drill through and blind holes at an angle

using swivel table of drilling

Objectives

At the end of this exercise you shall be able to

• file surface and right angle and check with try square

• file to size maintaining accuracy 0.02mm

• align the job for angular drilling

• drill angular through hole

• drill angular blind hole.

Job sequence

• Check the raw material for its size.

• Mark the required size and cut by hacksawing.

• File to size 75x24x24mm and check with vernier caliper.

• Mark the given dimension for drilling location as per size by using vernier height gauge.

• Punch on correct locations of drills

• Hold the work piece in the machine horizontally by keeping the parallel blocks under the work piece to avoid

drill bit tip touch the metal base of machine vice.

• Check with spirit level.

• Clamp the machine vice to the drilling machine universal table.

• Lock and arrest the table rotation in ‘z’ axis.

• Tilt the drilling machine table at an angle of 15°, lock it, and drill hole to the required depth.

• Align the spindle centre and hole location using locating pin.

43