Page 50 - CITS - Fitter - Trade Theory

P. 50

FITTER - CITS

LESSON 6 : Introduction of bench/pedestal grinder

Objectives

At the end of this lesson you shall be able to

• define the bench / pedestal grinder parts and function

• state the safety precaution while using it

• state the common defects and care maintenance.

Introduction of bench / pedestal grinder

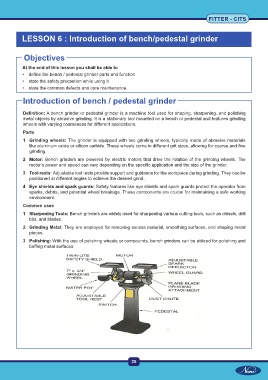

Definition: A bench grinder or pedestal grinder is a machine tool used for shaping, sharpening, and polishing

metal objects by abrasive grinding. It is a stationary tool mounted on a bench or pedestal and features grinding

wheels with varying coarseness for different applications.

Parts

1 Grinding wheels: The grinder is equipped with two grinding wheels, typically made of abrasive materials

like aluminum oxide or silicon carbide. These wheels come in different grit sizes, allowing for coarse and fine

grinding.

2 Motor: Bench grinders are powered by electric motors that drive the rotation of the grinding wheels. The

motor’s power and speed can vary depending on the specific application and the size of the grinder.

3 Tool rests: Adjustable tool rests provide support and guidance for the workpiece during grinding. They can be

positioned at different angles to achieve the desired grind.

4 Eye shields and spark guards: Safety features like eye shields and spark guards protect the operator from

sparks, debris, and potential wheel breakage. These components are crucial for maintaining a safe working

environment.

Common uses

1 Sharpening Tools: Bench grinders are widely used for sharpening various cutting tools, such as chisels, drill

bits, and blades.

2 Grinding Metal: They are employed for removing excess material, smoothing surfaces, and shaping metal

pieces.

3 Polishing: With the use of polishing wheels or compounds, bench grinders can be utilized for polishing and

buffing metal surfaces.

35

CITS : CG & M - Fitter - Lesson 5