Page 187 - CTS - Mechanic Diesel - TP

P. 187

MECHANIC DIESEL - CITS

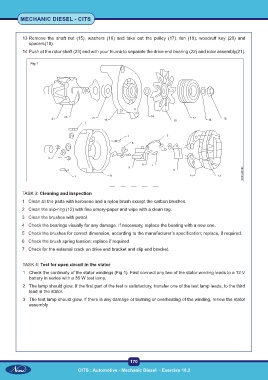

13 Remove the shaft nut (15), washers (16) and take out the pulley (17), fan (19), woodruff key (20) and

spacers(18).

14 Push at the rotor shaft (23) end with your thumb to separate the drive end bearing (22) and rotor assembly(21).

Fig 1

TASK 3: Cleaning and inspection

1 Clean all the parts with kerosene and a nylon brush except the carbon brushes.

2 Clean the slip-ring (12) with fine emery-paper and wipe with a clean rag.

3 Clean the brushes with petrol.

4 Check the bearings visually for any damage. If necessary, replace the bearing with a new one.

5 Check the brushes for correct dimension, according to the manufacturer’s specification; replace, if required.

6 Check the brush spring tension; replace if required.

7 Check for the external crack on drive end bracket and slip end bracket.

TASK 4: Test for open circuit in the stator

1 Check the continuity of the stator windings (Fig 1). First connect any two of the stator winding leads to a 12 V

battery in series with a 36 W test lamp.

2 The lamp should glow. If the first part of the test is satisfactory, transfer one of the test lamp leads, to the third

lead in the stator.

3 The test lamp should glow. If there is any damage or burning or overheating of the winding, renew the stator

assembly.

170

CITS : Automotive - Mechanic Diesel - Exercise 10.2