Page 347 - CTS - Mechanic Diesel - TP

P. 347

MECHANIC DIESEL - CITS

3 Remove the circlip for bores.

4 Remove the circlip for shafts.

5 Remove the mechanical seal and replace it when reassembling.

6 Remove the support washer

7 Mechanical seal reassembling should be made in the opposite order.

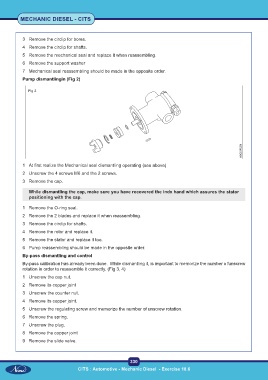

Pump dismantlingin (Fig 2)

Fig 2

1 At first realize the Mechanical seal dismantling operating (see above)

2 Unscrew the 4 screws M6 and the 2 screws.

3 Remove the cap.

While dismantling the cap, make sure you have recovered the indx hand which assures the stator

positioning with the cap.

1 Remove the O-ring seal.

2 Remove the 2 blades and replace it when reassembling.

3 Remove the circlip for shafts.

4 Remove the rotor and replace it.

5 Remove the stator and replace it too.

6 Pump reassembling should be made in the opposite order.

By-pass dismantling and control

By-pass calibration has already been done. While dismantling it, is important to memorize the number o funscrew

rotation in order to reassemble it correctly. (Fig 3, 4)

1 Unscrew the cap nut.

2 Remove its copper joint

3 Unscrew the counter nut.

4 Remove its copper joint.

5 Unscrew the regulating screw and memorize the number of unscrew rotation.

6 Remove the spring.

7 Unscrew the plug.

8 Remove the copper joint

9 Remove the slide valve.

330

CITS : Automotive - Mechanic Diesel - Exercise 18.6