Page 21 - Mechanic Diesel - TT

P. 21

MECHANIC DIESEL - CITS

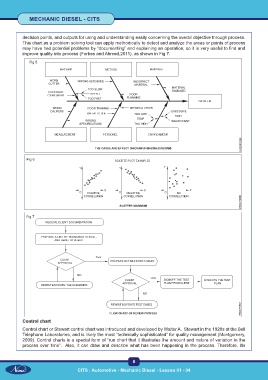

decision points, and outputs for using and understanding easily concerning the overall objective through process.

This chart as a problem solving tool can apply methodically to detect and analyze the areas or points of process

may have had potential problems by “documenting” and explaining an operation, so it is very useful to find and

improve quality into process (Forbes and Ahmed,2011), as shown in Fig 7.

Fig 5

Fig 6

Fig 7

Control chart

Control chart or Stewart control chart was introduced and developed by Walter A. Stewart in the 1920s at the Bell

Telephone Laboratories, and is likely the most “technically sophisticated” for quality management (Montgomery,

2009). Control charts is a special form of “run chart that it illustrates the amount and nature of variation in the

process over time”. Also, it can draw and describe what has been happening in the process. Therefore, itis

8

CITS : Automotive - Mechanic Diesel - Lesson 01 - 04