Page 310 - Mechanic Diesel - TT

P. 310

MECHANIC DIESEL - CITS

L. P. G. A multi valve is fitted on the tack. This valve is used to fill the gaps in the tank, forward the gas in the tank,

prevent gas leakage and show the gas level in the tank. Next in this valve Components include:

• Filler intake and manually closable filler closing tap to fill the tank with gas.

• Filler stop valve to stop the gas filling operation after filling the tank to a certain level.

• Check valve provided to prevent gas leakage.

• A gauge on the top surface of the tank to indicate the level of gas in the tank and pointer, consists of float,

pinion gear, gear, permanent magnet and metal diaphragm mounted inside the multi valve body. In Tank.

L.P.G. of gas when the temperature rises after filling 80% + 5% limit in tank to avoid tank explosion due to

volume expansion L. P. G. It has to be paid. L more than 80% of tank capacity. P. G. When filling the tank, the

multivalve stops the flow of gas beyond 80%. A multivalve prevents gas from escaping from the tank when the

gas tube supplying the engine breaks in an accident.

2 High Pressure Tube: High pressure tubes of annealed copper are used to convey the gas from the tack to

the solenoid valve and from the solenoid valve to the pressure reducer. The working pressure of these tubes

is 45 bar and they are connected with the help of special union. They are fitted with clips in alignment so that

they are separated from the exhaust pipe and the car body.

3 Gas-Petrol Change Over Switch: Switching on Gas Supply System or Petrol Fuel Supply System

A push button type electric switch is provided for this. This switch is mounted on the dash board so that it can

be easily operated by the driver from the driving seat.

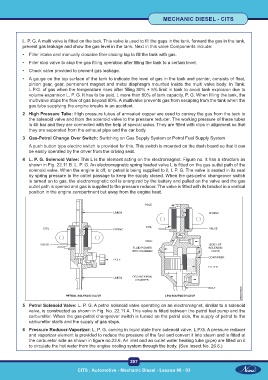

4 L. P. G. Solenoid Valve: This L is the element acting on the electromagnet. Figure no. It has a structure as

shown in Fig. 22.11 B. L. P. G. An electromagnetic spring loaded valve L is fitted on the gas outlet path of the

solenoid valve. When the engine is off, or petrol is being supplied to it, L P. G. The valve is seated in its seat

by spring pressure in the outlet passage to keep the supply closed. When the gas-petrol changeover switch

is turned on to gas, the electromagnetic coil is energized by the battery and pulled on the valve and the gas

outlet path is opened and gas is supplied to the pressure reducer. The valve is fitted with its bracket in a vertical

position in the engine compartment but away from the engine heat.

5 Petrol Solenoid Valve: L. P. G. A petrol solenoid valve operating on an electromagnet, similar to a solenoid

valve, is constructed as shown in Fig. No. 22.11 A. This valve is fitted between the petrol fuel pump and the

carburettor. When the gas-petrol changeover switch is turned on the petrol side, the supply of petrol to the

carburettor starts and the supply of gas stops.

6 Pressure Reducer-Vaporizer: L. P. G. coming in liquid state from solenoid valve. L.P.G. A pressure reducer

and vaporizer element is provided to reduce the pressure of the fuel and convert it into steam and is fitted at

the carburetor side as shown in figure no.22.6. An inlet and an outlet water heating tube (pipe) are fitted on it

to circulate the hot water from the engine cooling system through the body. (See Insect No. 26.6.)

297

CITS : Automotive - Mechanic Diesel - Lesson 88 - 93 CITS : Automotive - Mechanic Diesel - Lesson 88 - 93